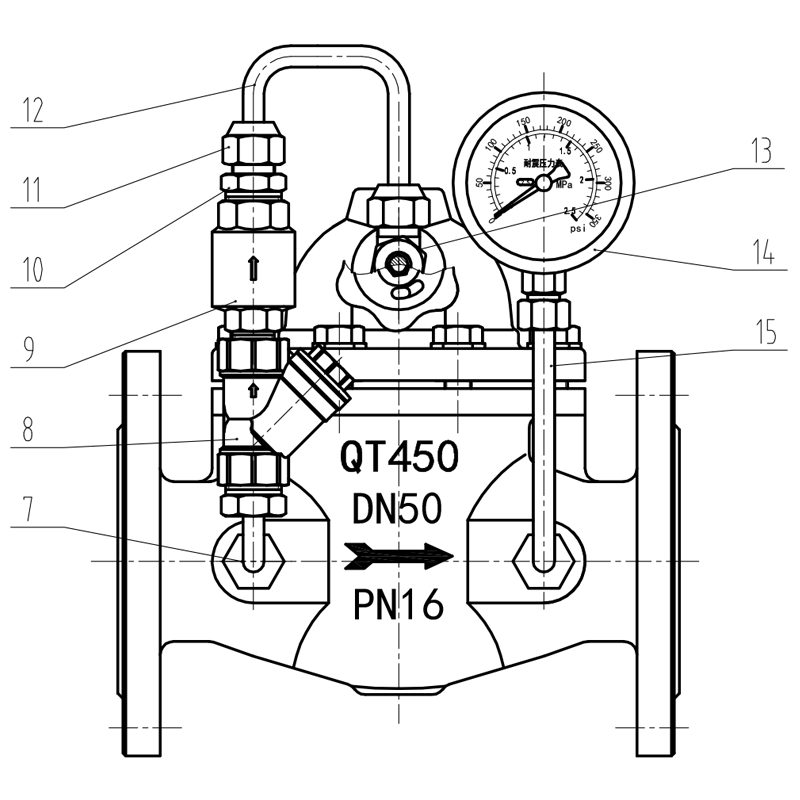

300X-16Q Slow Closing Check Valve

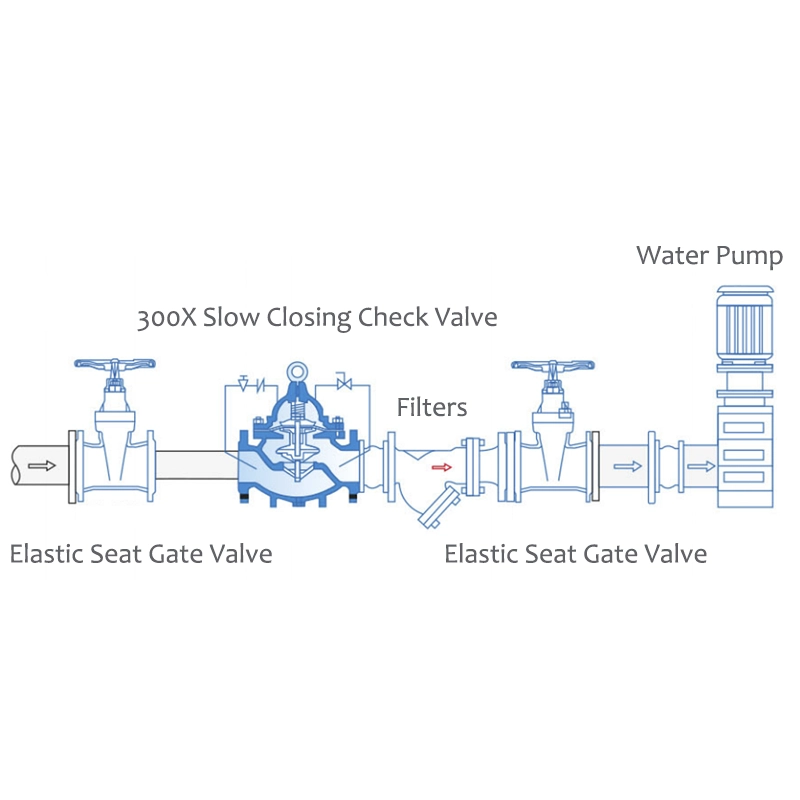

The 300X-16Q Slow Closing Check Valve prevents backflow via a delayed closing mechanism, reducing water hammer and noise. With adjustable slow closing (0°C-80°C, max 16 bar), it protects pumps/pipelines in water supply, HVAC, and industrial systems.

See more at Check Valve!

300X-16Q Slow Closing Check Valve

SPECIFICATIONS

1.Slow Closing Check Valve is a special check valve that reduces water hammer impact and noise through delayed closing mechanism.

2.Its core function is to prevent medium back flow, and at the same time, the slow closing design can alleviate the pressure fluctuation when the valve is closed

3.Protecting the pipeline system from water hammer damage

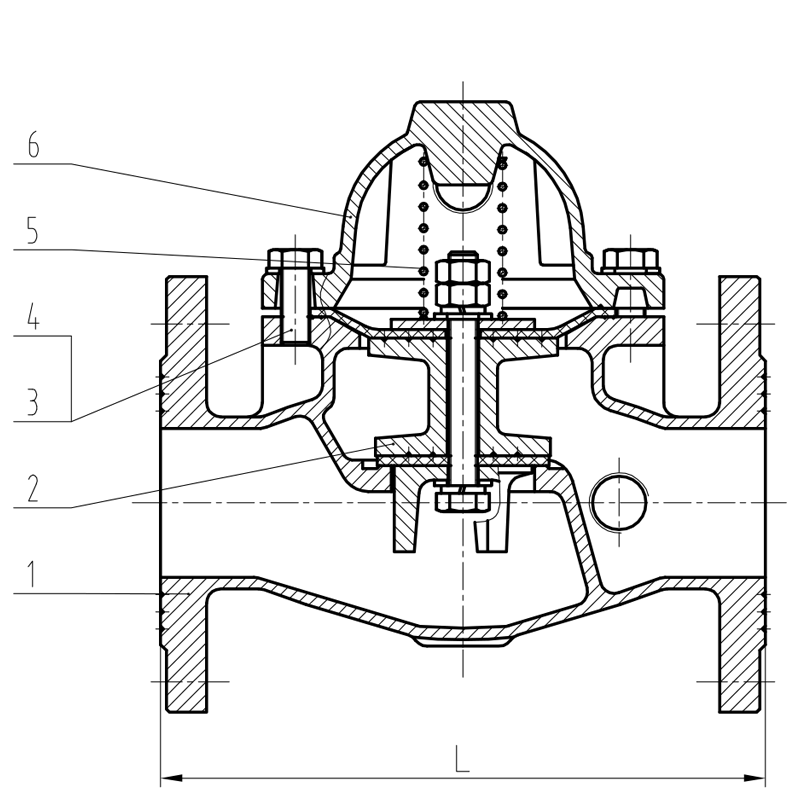

Working principle

1.Opening process: When the medium flows forward, the pressure pushes the valve disc to open, and the fluid passes smoothly.

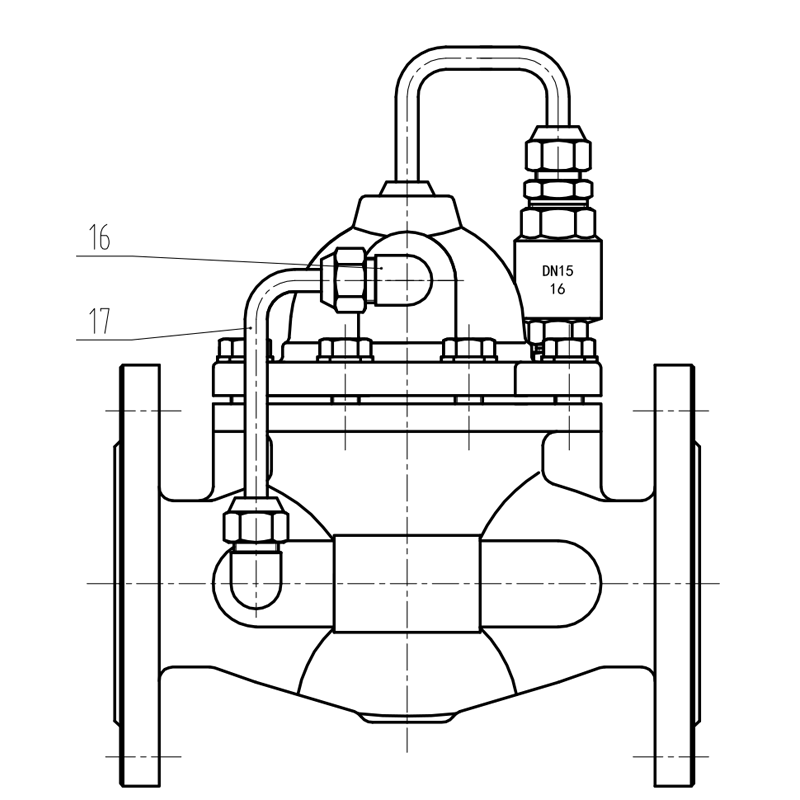

2.Slow closing process: When the medium flow rate decreases or stops, the valve disc slowly closes under the action of the slow closing mechanism (such as damper, spring) to avoid the high-pressure shock wave (water hammer) caused by instantaneous closing.

3.Complete sealing: The valve disc is finally completely closed to block the back flow of the medium.

FEATURE :

1.Water hammer protection:The slow closing design significantly reduces the pressure surge in the pipeline system caused by the rapid closing of the valve, protecting the pump, pipeline and connected equipment.

2.Low noise operation:Slow closing reduces the impact sound of the valve disc and the valve seat, suitable for noise-sensitive environments such as hospitals and residential areas.

3.Extend equipment life:Reducing water hammer impact can avoid pipeline vibration and joint leakage, and extend the service life of water pumps, valves and pipelines.

4.Adapt to complex working conditions:The slow closing time can be adjusted (through dampers or spring preload), suitable for systems with different flow and pressure.

Typical application scenarios

1.Water supply and drainage system: prevent water back flow at the pump outlet when the pump is stopped, and avoid reverse damage to the pump body.

2.Firefighting network: maintain one-way water supply to the fire water tank or pipeline to prevent water hammer caused by sudden pressure drop.

3.Heating, ventilation and air conditioning (HVAC): protect heat exchangers and water pumps in the circulating water system.

4.Industrial pipeline: pipelines for transporting easily vaporized liquids or gas-containing media in industries such as chemical and electric power.

5.Long-distance water pipeline: reduce the impact of pressure fluctuations caused by valve closure on the pipeline.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message