Fixed Foam Bladder Tank For Foam Suppression System

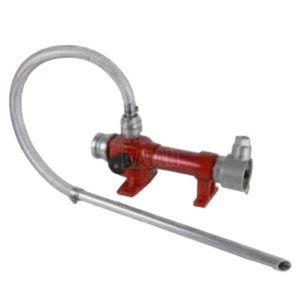

The Fixed Foam Bladder Tank For Foam Suppression System features a manual batcher, dispenser flange to ANSI/BS4504/GB standards, carbon steel valve body with rubber liner, and carbon steel dispensers, ball valves, safety valves and pipeline system (SS304 optional for each).

See more at Foam Storage Equipment Catalog!

Fixed Foam Bladder Tank For Foam Suppression System

Specifications

1. Structure: manual batcher

2. Dispenser flange standard: ANSI / BS4504 / GB;

3. Valve body material: carbon steel;

4. Liner material: rubber;

5. Dispenser: standard carbon steel (optional SS304 stainless steel);

6. Ball valve: standard brass (optional SS304 stainless steel);

7. Safety valve: standard brass (optional SS304 stainless steel);

8. Pipeline system: standard carbon steel (optional SS304 stainless steel)

Application scenarios

1. High-risk explosion-proof areas: refinery storage tank area, chemical plant reactor, LNG storage and transportation facilities.

2. Continuous flame suppression requirements: oil flowing fire (capsule liquid supply ensures continuous foam coverage for 30min+).

3. Corrosive environment: offshore platform (316SS tank body resistant to salt spray), acid depot (butyl rubber resistant to pH 1~13).

Working principle

Fire protection network pressure water → Inject into tank to squeeze capsule → Foam liquid quantitative output → Proportional mixer → Generate 3%/6% mixed liquid → Foam injection device to suppress fire → Capsule emptying → Automatic switching to pure water cooling

Features

1. Zero cross contamination: Capsules physically isolate foam liquid and water to avoid premixed degradation (foam validity period extended ≥50%)

2. Ultra-high emptying rate: Foam residue ≤1% (capsule shrinkage rate ≥98%, far exceeding the 85% standard of traditional pressure tanks)

3. Extreme environment adaptation

Temperature: -40℃~120℃ (capsules are resistant to hydrocarbon solvents)

4. Intelligent monitoring: magnetostrictive level gauge + pressure transmitter (accuracy ±0.5%), linked BMS system real-time alarm

5. Maintenance economy: Capsule life 10 years (replacement cost is only 15% of tank reset)

Working pressure

1. Design pressure: 1.0~2.5 MPa

2. Capsule bursting pressure: ≥3×working pressure (ISO 1402 test)

3.Minimum starting pressure 0.3 MPa (to ensure reliable triggering of low flow system)

Leave Your Message