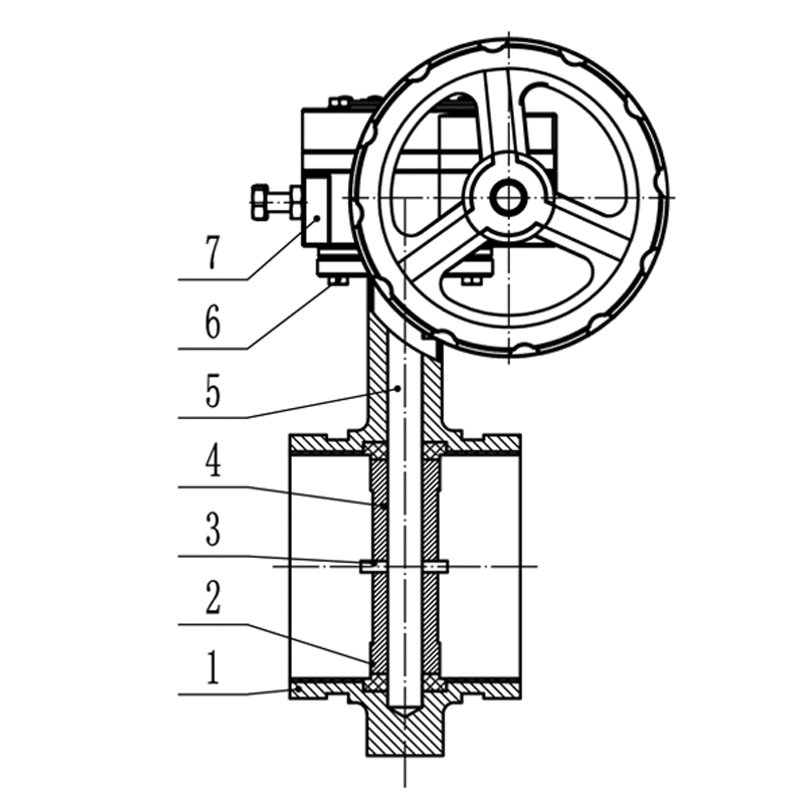

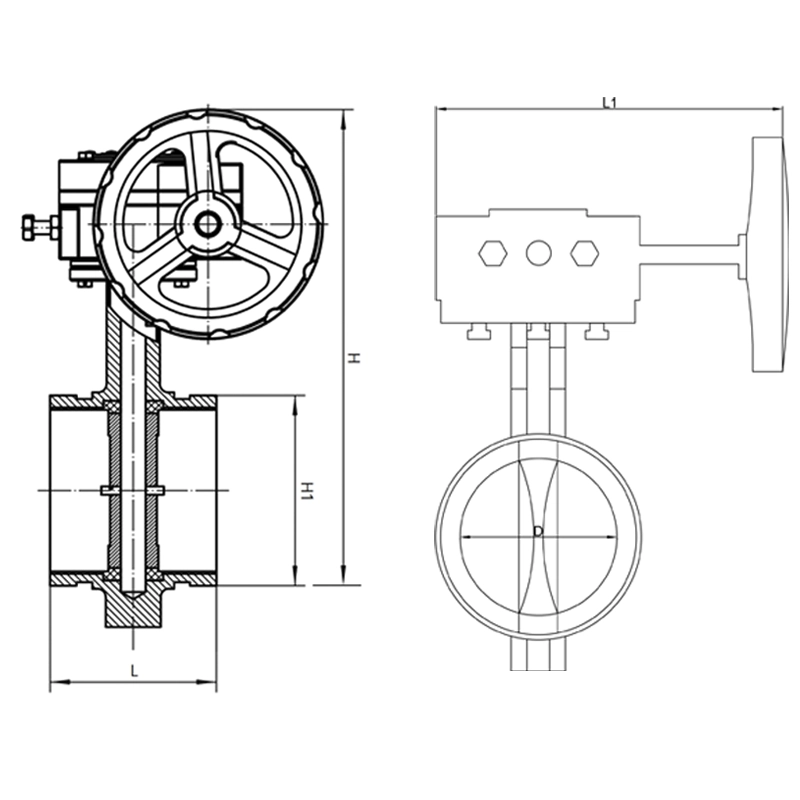

D381X-16Q Grooved Turbine Butterfly Valve

The D381X-16Q Grooved Turbine Butterfly Valve features groove connections and turbine drives for high-torque operation, enabling 0°-90° disc rotation for flow control. Suitable for PN10-PN16 systems in municipal and industrial applications, it offers quick installation, easy maintenance, and a 0°C-80°C temperature range with epoxy coating.

See the Butterfly Valve Catalog for more info!

D381X-16Q Grooved Turbine Butterfly Valve

PRODUCT DESCRIPTION

1.Grooved turbine butterfly valve is a butterfly valve that combines groove connection with turbine transmission mechanism.

2. It is widely used in fluid pipeline systems such as fire protection, water supply and drainage, HVAC, etc.

3.Turn the handwheel to drive the worm gear mechanism, drive the valve stem to rotate, and make the valve plate rotate around the axis.

4.The valve plate is fully closed at 0° and fully open at 90°. The flow rate is adjusted by the intermediate angle.

5.The turbine drive provides high mechanical efficiency and is suitable for large-caliber and high-pressure working conditions.

FEATURES

1.Quick installation:Groove connection does not require welding or flange docking, saving installation time and labor costs.

2.Effortless operation:Turbine transmission is more labor-saving than handle operation

3.Pressure and temperature resistance:The nominal pressure is usually PN10-PN16, and the applicable temperature range is: -0℃~80℃ (depending on the sealing material).

4.Easy maintenance:The sealing ring can be replaced online without disassembling the valve body.

5.Widely used:Compatible with water, gas, oil and weakly corrosive media.

APPLICATION

1.Municipal engineering: large water supply network, sewage treatment plant pump station opening and closing and flow control.

2.Petrochemical: medium and high pressure pipelines for crude oil and chemical media (such as PN16~PN25).

3.Power industry: circulating water system, cooling water pipeline regulation.

4.Industrial system: large-diameter air ducts for ventilation, dust removal and flue gas treatment (such as DN1000 and above)

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message