In complex fluid transport systems, maintaining stable pressure is crucial for ensuring safety, improving efficiency, and extending equipment lifespan. Pressure reducing valves are the core control components in this process. Among them, flanged pressure reducing valves and grooved pressure reducing valves, with their unique designs, have become preferred solutions for different application scenarios. This article will briefly introduce the characteristics and value of these two types of valves.

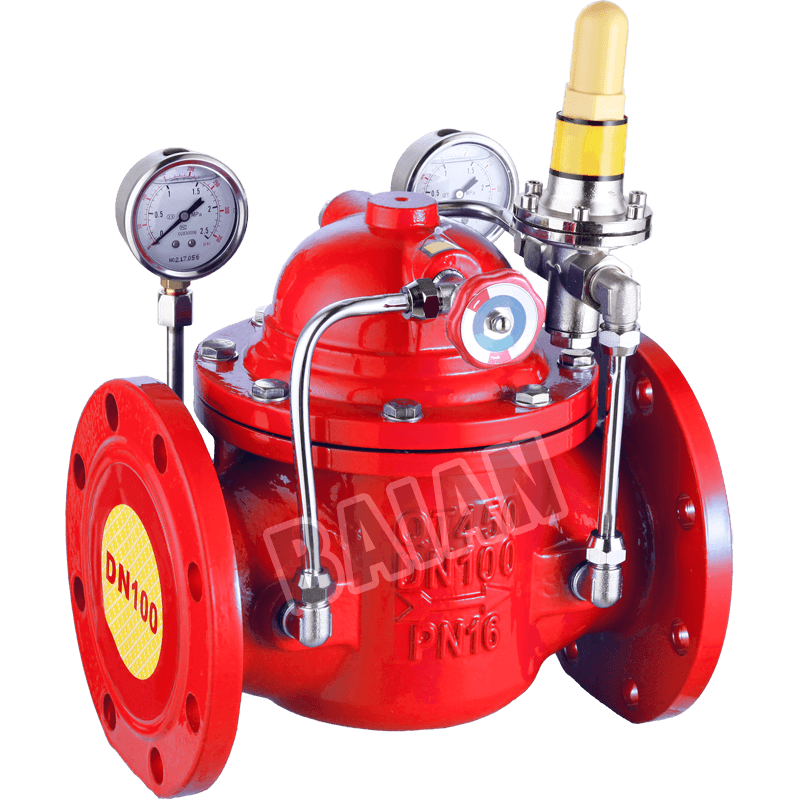

I. Flanged Pressure Reducing Valves: A Robust and Reliable System Foundation

- Flanged pressure reducing valves are bolted to the pipeline via standard flanges at both ends of the valve body. This structure determines its main characteristics:

- High Strength and Sealing: The flange connection provides excellent structural strength and sealing performance, reliably withstanding high system pressures and effectively preventing leakage, making it suitable for applications with stringent safety requirements.

- Wide Applicability: Its standardized interface allows for easy adaptation to various industrial piping systems, offering strong versatility.

- Core Function: It acts as a “precise regulator” of system pressure, stably reducing and maintaining high, fluctuating pressure at the inlet to the required set value. Regardless of upstream pressure fluctuations, it ensures downstream equipment (such as instruments, sprinkler systems, and domestic water taps) operates under safe and constant pressure, preventing damage or danger caused by overpressure.

- Main Advantages: Stable connection, high pressure resistance, excellent sealing, suitable for high-pressure, large-diameter main water supply pipelines, industrial process systems, and fire protection networks with extremely high reliability requirements.

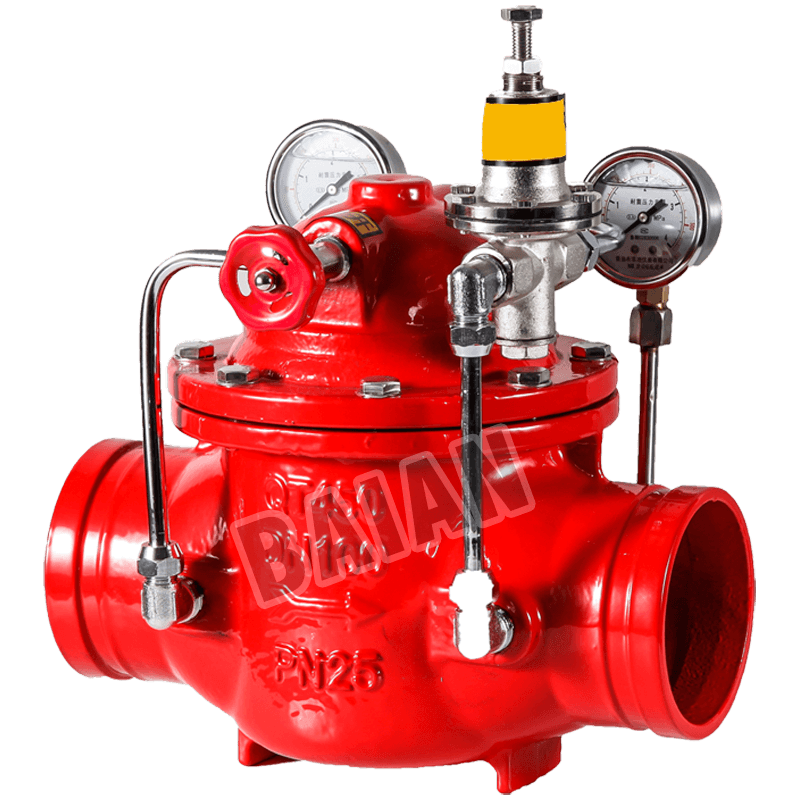

II. Grooved Pressure Reducing Valve: A Pioneer in Efficient and Flexible Installation

- Grooved pressure reducing valves utilize advanced grooved clamp connection technology. Installation simply involves aligning the valve’s groove with the pipe’s groove and tightening the clamp.

- Ease of Installation: The biggest advantage is extremely fast installation, eliminating the need for welding or complex flange connections, significantly saving labor and time costs, making it particularly suitable for projects with tight schedules or renovations.

- Simple Maintenance: The clamp connection method makes valve disassembly and replacement exceptionally convenient, significantly reducing downtime during system maintenance and partial upgrades.

- Core Function: Its pressure reducing efficiency is as excellent as flanged types, enabling precise control of downstream pressure. Meanwhile, due to their installation flexibility, they are often used in situations requiring rapid deployment, frequent system adjustments, or limited space, such as fire sprinkler branch pipes, air conditioning water systems, and water supply branch pipes for process equipment within buildings.

- Main advantages: Quick and flexible installation, easy maintenance, easy system modification, significantly reducing overall installation and maintenance costs, making them an ideal choice for modern, efficient construction.

Summary

Whether it’s the robust, pressure-bearing flange pressure reducing valve or the quick-installation, easy-maintaining grooved pressure reducing valve, their core mission is to provide reliable and stable pressure control for your pipeline system. Through automatic adjustment, they effectively prevent water hammer, overpressure, and other hazards, directly protecting expensive downstream equipment and terminal devices. They are key components for improving the overall safety, stability, and economy of the system. Choosing the appropriate type based on your system pressure, pipe diameter, installation conditions, and maintenance needs will bring long-term reliable operation assurance to your project.