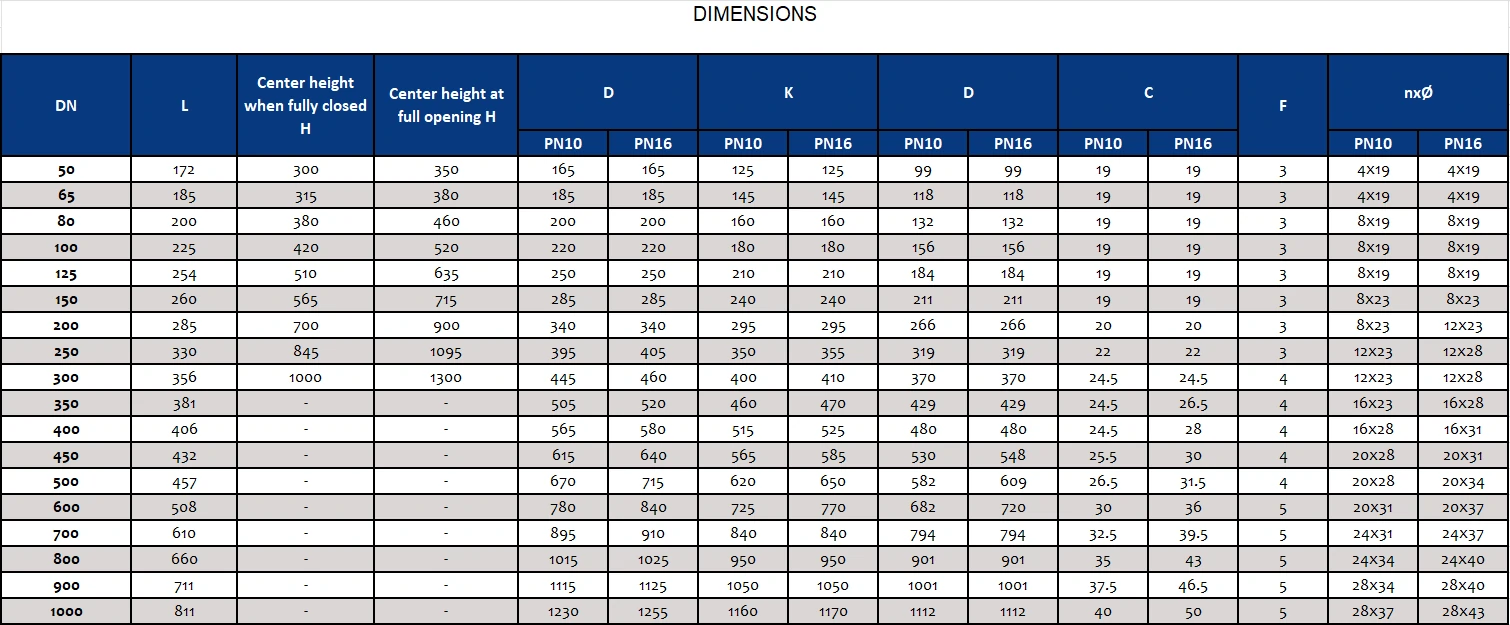

Z41X-16Q OS&Y Hard Seal Seated Gate Valve

The Z41X – 16Q OS&Y Hard Seal Seated Gate Valve is a flange – connected industrial valve with a rising stem. Designed for high – temp/pressure and corrosive environments, it features hard alloy seals, offers 16 bar max pressure, 0°C – 80°C range, and epoxy coating, suitable for petrochemical, power, and metallurgical applications.

See the Gate Valve Catalog for more information

Z41X-16Q OS&Y Hard Seal Seated Gate Valve

PRODUCT DESCRIPTION

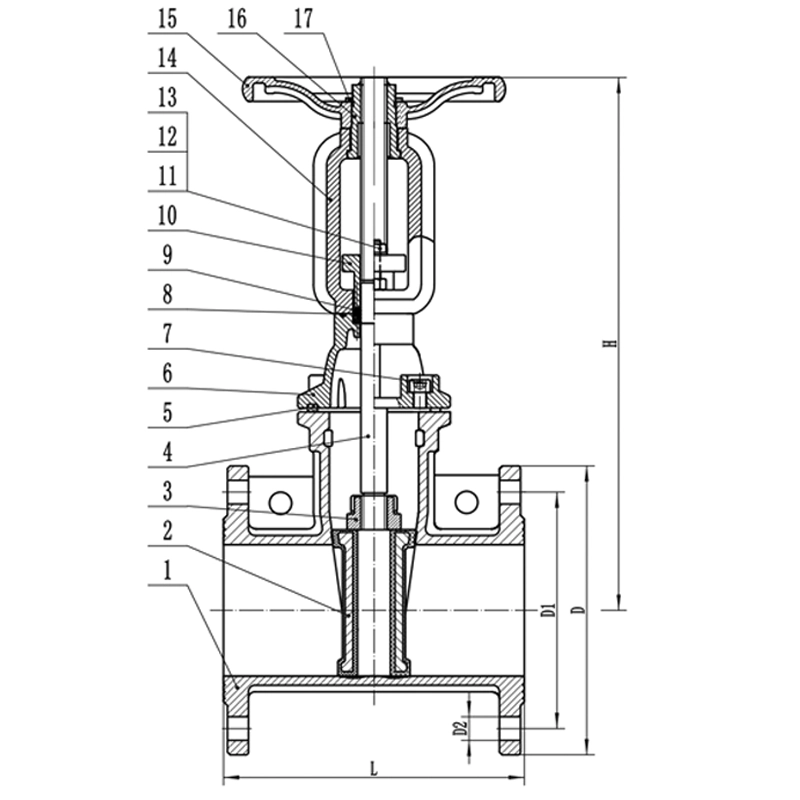

1.Flange rising stem hard seal gate valve is an industrial valve that connects pipelines through flanges, adopts rising stem lifting structure and hard seal design.

2.Its core function is to reliably cut off or connect fluids.

3.It is suitable for harsh working conditions such as high temperature, high pressure, corrosive media.

4.The valve stem is exposed and rises and falls with the opening and closing of the valve, intuitively displaying the opening status for easy operation and monitoring.

5.The sealing surface is made of metal cladding hard alloy or special metal pairing, which is resistant to high temperature and high pressure, wear and corrosion.

FEATURES

1.High temperature and high pressure adaptability: The hard seal structure maintains excellent sealing performance under extreme working conditions, avoiding the aging problem of soft seal materials.

2.Long life design: Wear-resistant sealing surface and anti-corrosion material extend the service life of the valve and reduce the replacement frequency.

3.Convenient maintenance: Flange connection simplifies disassembly and assembly, and the open stem structure facilitates lubrication and status inspection.

4.Wide compatibility: Multi-standard flange interface adapts to the world's mainstream pipeline systems.

APPLICATION

1.It is used in petroleum.

2.Chemical.

3.Electric power.

4.Metallurgy and municipal engineering.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message