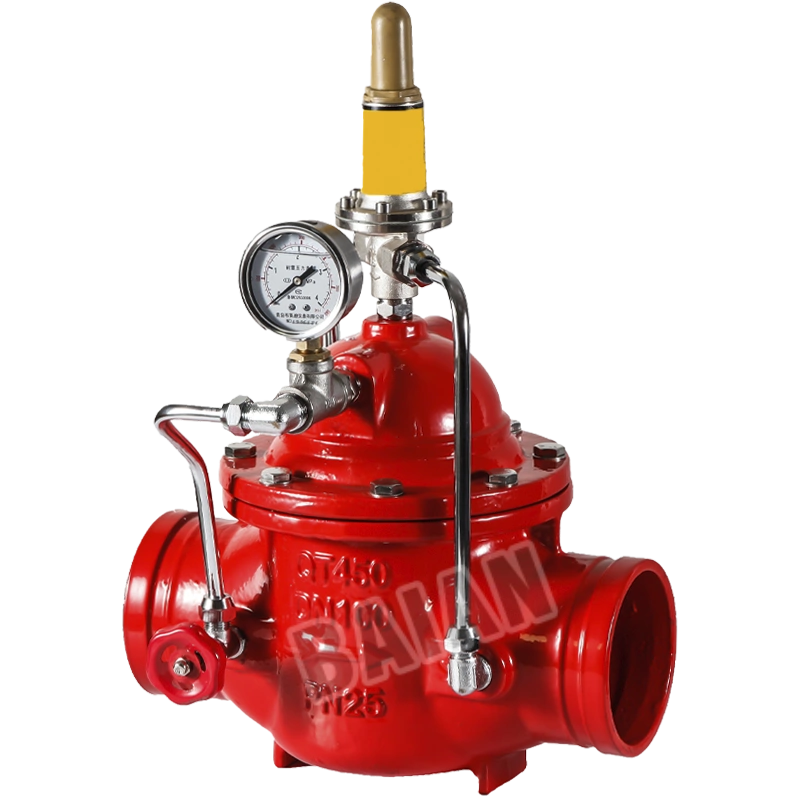

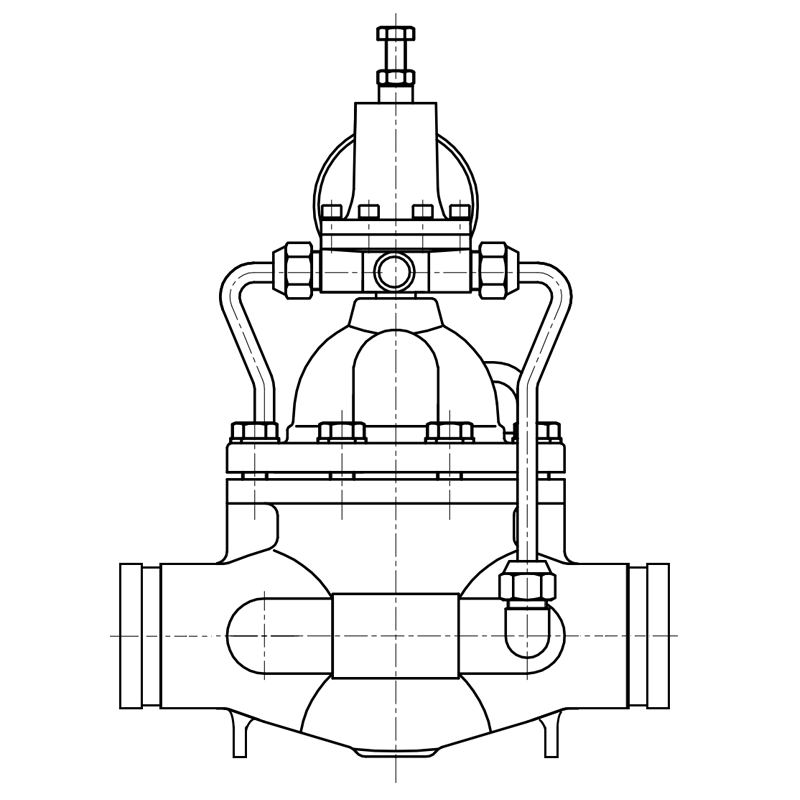

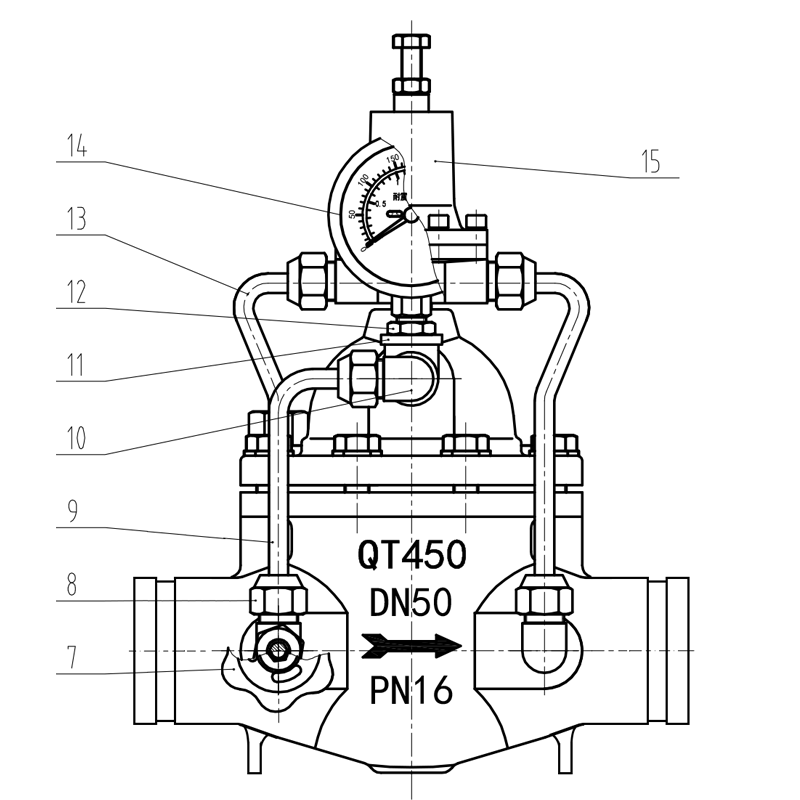

8500X-16Q Grooved Type Pressure Relief Valve

The Grooved Type Pressure Relief Valve automatically releases excess pipeline pressure to ensure system safety, with groove connection for quick installation, adjustable relief threshold, and max 16 bar pressure, suitable for fire protection, water supply, and industrial pipelines.

See the Pressure Relief Valve Catalog for more info!

8500X-16Q Grooved Type Pressure Relief Valve

PRODUCT DESCRIPTION

1.A grooved pressure relief valve is a valve used to release over pressure in a pipeline system and protect the system safety.

2.It is usually used in conjunction with a grooved pipe connection system.

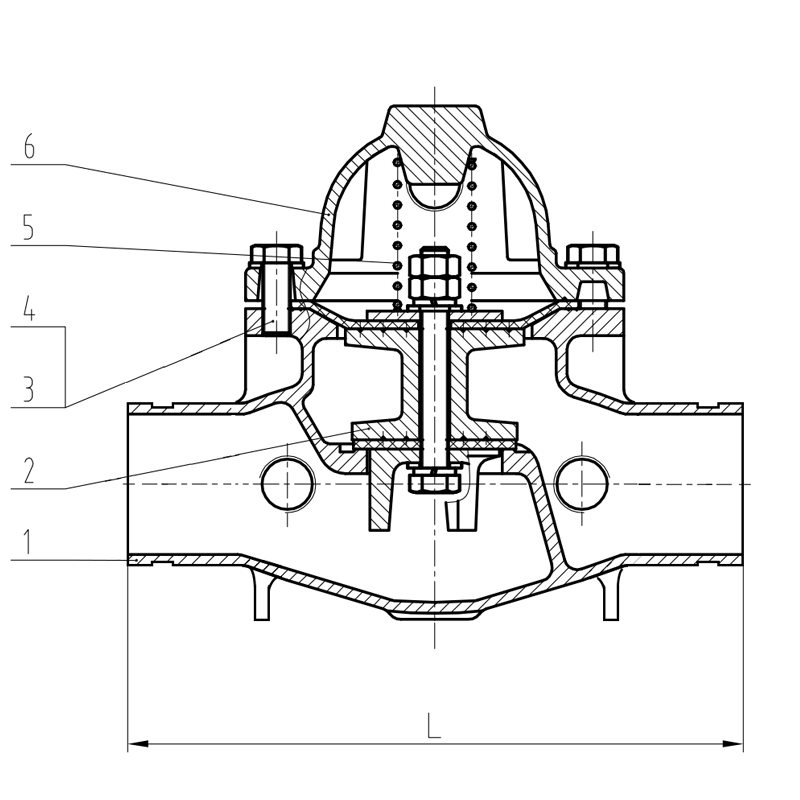

3.Normal state: When the system pressure is lower than the set value, the spring force makes the valve disc/diaphragm close to the valve seat and the valve is closed.

4.Over pressure relief: When the pressure exceeds the set value, the medium pressure overcomes the spring force, pushes the valve disc open, and releases excess pressure.

5.Pressure recovery: After the pressure falls back to the safe range, the spring pushes the valve disc to reset and the valve closes.

FEATURES

1.Quick installation: Groove connection does not require welding or thread processing, saving installation time and cost.

2.Automatic response: No external control is required, and it automatically opens and closes based on system pressure changes.

3.Adjustable pressure: The pressure relief threshold can be adjusted according to needs, with a wide range of applications.

4.Easy maintenance: Modular design supports quick disassembly and replacement of seals.

5.Compatibility: Suitable for a variety of media such as water, gas, and firefighting foam.

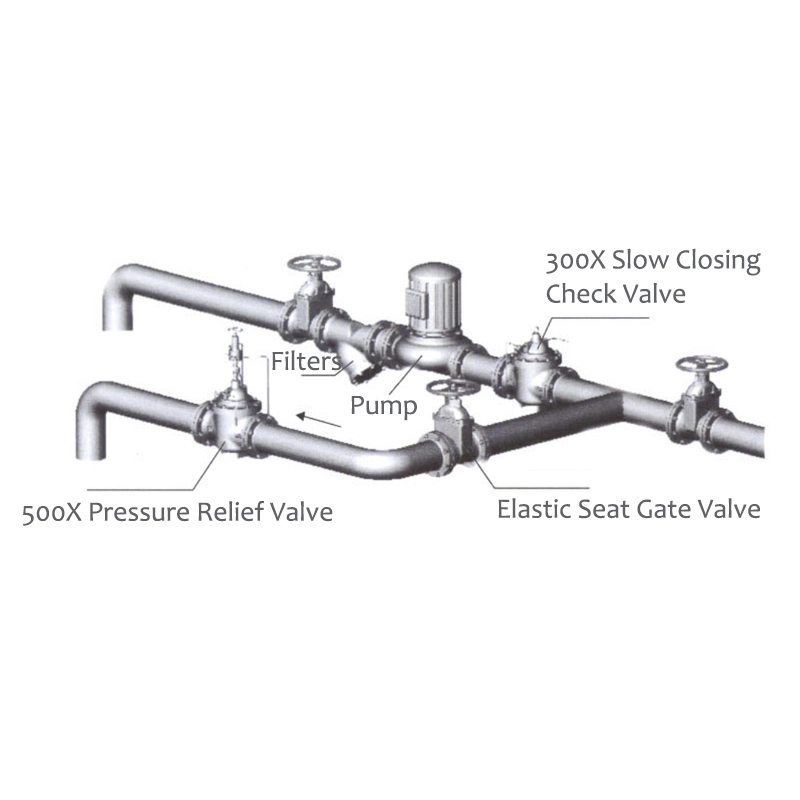

Application

1.Fire protection system: protect sprinkler pipes, fire hydrants, etc. from water hammer or pressure fluctuations.

2.Water supply and drainage system: prevent over pressure caused by pump start and stop or valve misoperation.

3.Industrial pipeline: protection of pressure vessels or pipelines in the fields of chemical, HVAC, energy, etc.

4.High-rise buildings: balance the water pressure difference between floors to avoid pipeline rupture.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi)

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test

SET PRESSURE

Factory pre-set outlet pressure to 10 bar (144psi)

TEMPERATURE RANGE

0 °C to 80°C

COATING

Fusion Bonded Epoxy Coating

Leave Your Message