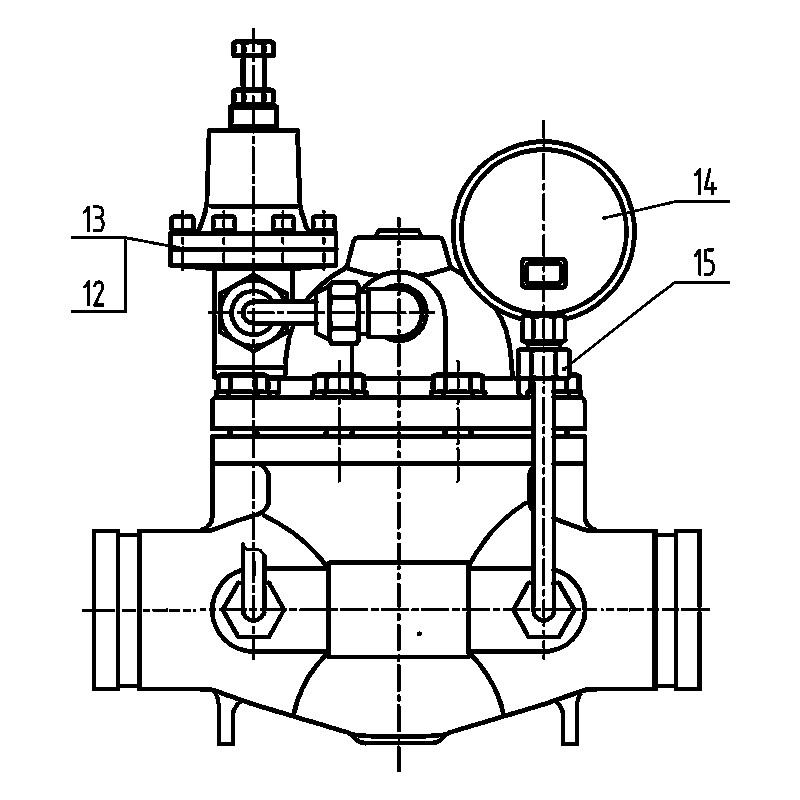

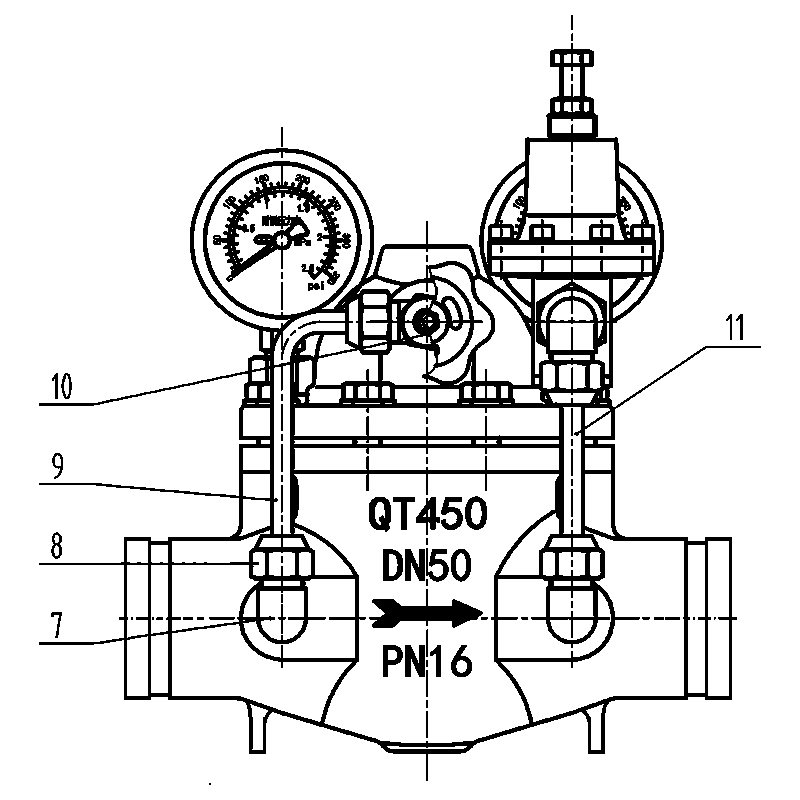

8200X-16Q Grooved Type Pressure Reducing Valve

The 8200X-16Q Grooved Type Pressure Reducing Valve is designed for high-rise buildings, integrating electric valve, check valve, and water hammer eliminator functions, with a max 16 bar pressure, 0°C-80°C range, and epoxy coating.

See more at Pressure Reducing Valve Catalog!

8200X-16Q Grooved Type Pressure Reducing Valve

SPECIFICATIONS

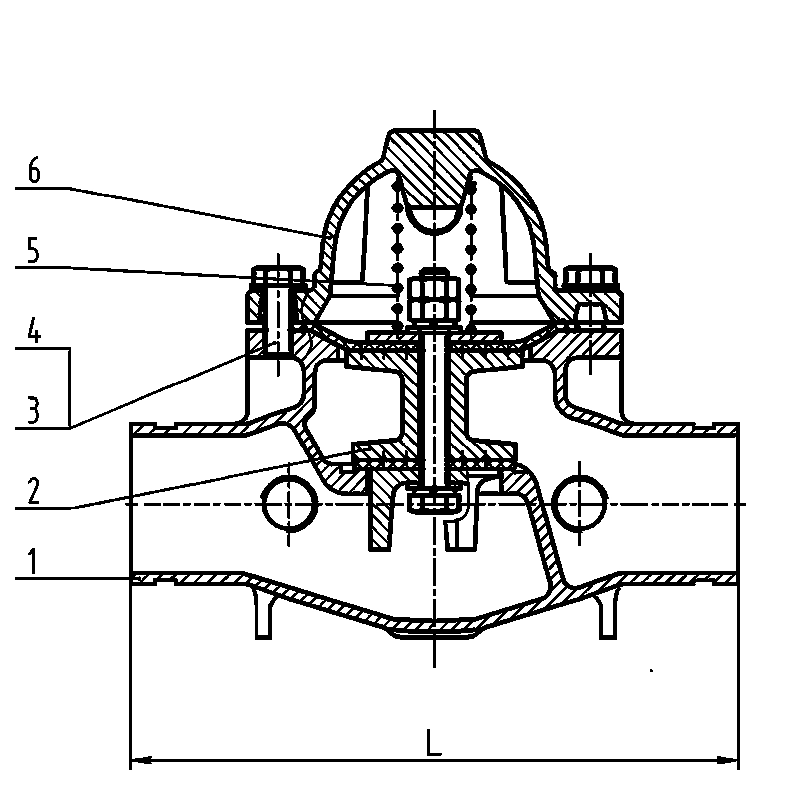

1.This product is designed for high-rise and super high-rise buildings, and is used to solve the problems of high-rise building domestic water and fire water systems, which require large flow, high sensitivity, small flow resistance, good check density effect, and no water hammer.

2.This product has the characteristics of reasonable design and long service life.

3.This valve has three functions of electric valve, check valve and water hammer eliminator, which can effectively improve the safety and reliability of water supply system,

4.Integrate the technical principles of slow opening, fast closing and slow closing to eliminate water hammer, to prevent the occurrence of water hammer when starting and stopping the pump.

5. Only need to operate the water pump electric pump, and the valve can automatically open and close according to the water pump operating procedures.

6.This valve has a large flow, small pressure loss, reliable sealing performance, convenient installation, maintenance, commissioning and inspection, and a long service life.

7.Adjustment range ofoutlet pressure: 4.5 to 11.4 bar(65 to 165 psi)

FEATURES :

1.Novel structure, reasonable use of hydraulic principle control theory.

2.Stable and reliable operation, large flow rate.

3.The valve disc opens quickly and closes slowly, without water hammer impact, and the closing time is adjustable.

4.Good check seal effect and long service life.

5.Easy installation and maintenance.

Installation requirements

1.A filter must be installed before the slow closing silencer check valve.

2.When installing, pay attention to the direction of the arrow on the valve body. For maintenance, leave a certain amount of space around the check valve.

3.A check valve of the corresponding diameter should be installed in a position that can ensure that the water source is cut off when the check valve is repaired.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi)

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test

SET PRESSURE

Factory pre-set outlet pressure to 10 bar (144psi)

TEMPERATURE RANGE

0 °C to 80°C

COATING

Fusion Bonded Epoxy Coating

Leave Your Message