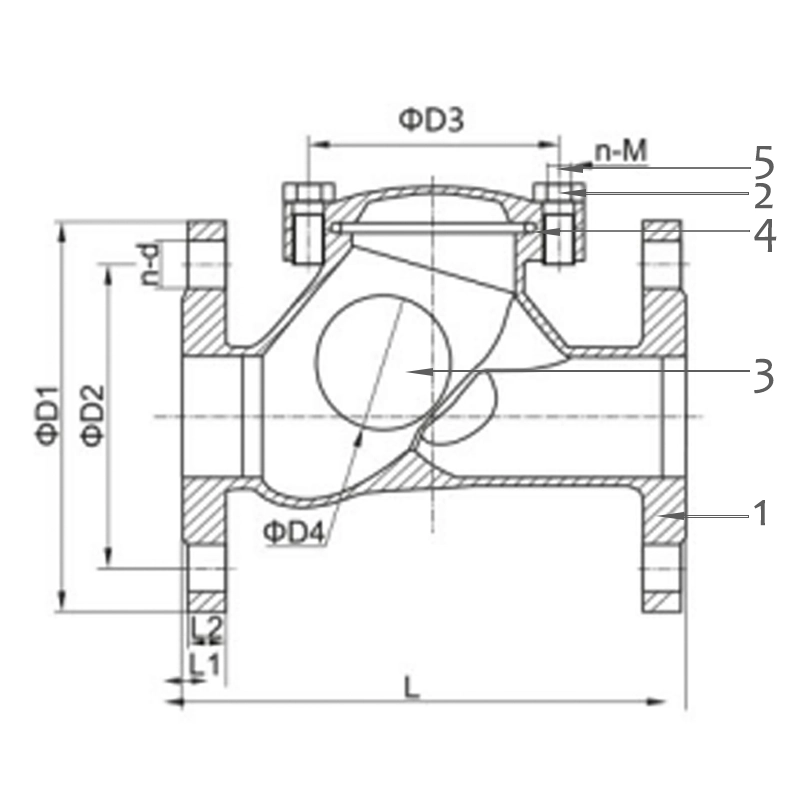

HQ41X-16Q Check Ball Valve

The HQ41X-16Q Check Ball Valve is a compact one-way valve using a spring-assisted ball for quick on/off (≤0.1s). With high sealing (≤0.01% leakage) and particle resistance, it suits water, industrial fluids, and irrigation at max 16 bar and 0°C-80°C.

See more at Check Valve Catalog!

HQ41X-16Q Check Ball Valve

PRODUCT DESCRIPTION

1.Ball Check Valve is a one-way valve that uses a free-floating or spring-assisted ball as an opening and closing member.

2.When the medium flows forward, the ball is pushed open, and when it flows reversely, the ball quickly returns to its original position and seals under the action of gravity, medium pressure or spring to prevent back flow.

3.It has a compact structure and can be opened and closed quickly

4.Is suitable for pipelines containing liquids, gases and particles

FEATURES

1.Fast response The ball has small inertia and short closing time (≤0.1 seconds) to prevent back flow of the medium.

2.High sealing The ball surface is in full contact with the valve seat, and the leakage rate is ≤0.01%

3.Resistant to particle media There is no dead angle for guidance, and the ball can push away tiny particles when rolling, and it is not easy to get stuck (suitable for fluids containing impurities).

4.Low pressure loss Straight-through flow channel design, the flow capacity is more than 90% when fully open.

5.Multi-directional installation Supports horizontal, vertical (flow direction from bottom to top) or inclined installation to adapt to complex pipeline layouts.

APPLICATION

1.Water supply and drainage system: municipal sewage pipe network, rainwater discharge pipe back flow prevention.

2.Industrial fluid: corrosive medium transmission pipelines in chemical and paper mills.

3.Agricultural irrigation: water pump outlet to prevent shutdown back flow.

4.Building drainage: basement drainage pipes, rainwater recovery system.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message