D341X-16Q Flange Turbine Type Butterfly Valve

The D341X-16Q Flange Turbine Type Butterfly Valve uses turbine-driven 90° disc rotation for precise flow control, with flange connections for PN16-PN25 pressure resistance. Suitable for high-pressure industrial systems, it offers 70% less operating force, 0°C-80°C range, and epoxy coating for durability.

See the Butterfly Valve Catalog for more information!

D341X-16Q Flange Turbine Type Butterfly Valve

PRODUCT DESCRIPTION

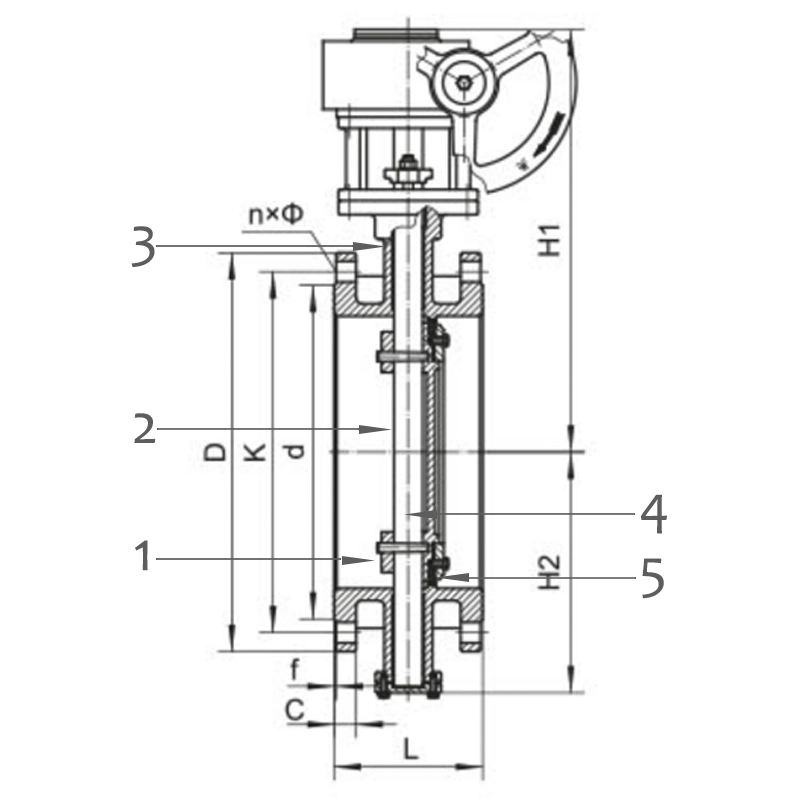

1.Rotate the turbine handwheel, drive the turbine through the worm, drive the valve stem and valve plate to rotate 90°, and realize full opening, full closing or flow adjustment of the valve.

2.The valve plate opening can be accurately controlled by the handwheel dial (0° fully closed, 90° fully open), and the flow adjustment linearity is better than that of the handle-type butterfly valve.

3.The rigid structure of the flange connection can effectively disperse the pipeline stress and ensure reliable sealing under high pressure conditions.

FEATURES

1.Pressure resistance PN16-PN25

2.Temperature range 0℃~80℃

3.Operating torque Turbine transmission reduces the operating force by more than 70%, and the DN1200 valve can be operated by one person.

4.Sealing level Elastic seal can reach zero leakage, and metal hard seal can meet high temperature and harsh working conditions.

5.Life and maintenance The valve seat can be replaced online, and the turbine box has a long maintenance-free period (grease is replaced every 5 years)

APPLICATION

1.Energy industry: steam pipelines in thermal power plants, cooling water systems in nuclear power plants.

2.Petrochemicals: crude oil pipelines, reactor inlet and outlet control, high-temperature cracking units.

3.Shipbuilding and marine engineering: desalination systems, ballast water management.

4.Metallurgical industry: blast furnace cooling water, high-temperature flue gas treatment.

5.Municipal engineering: high-pressure water pumping stations, long-distance water supply mains.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message