Стационарный резервуар для пенообразователя для системы пеноподавления

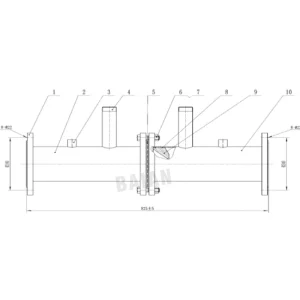

Сайт Стационарный резервуар для пенообразователя для системы пеноподавления Имеет ручной дозатор, фланец дозатора по стандартам ANSI/BS4504/GB, корпус клапана из углеродистой стали с резиновой прокладкой, а также дозаторы, шаровые краны, предохранительные клапаны и трубопроводную систему из углеродистой стали (SS304 - опция для каждого).

См. подробнее Оборудование для хранения пены Каталог!

Стационарный резервуар для пенообразователя для системы пеноподавления

Технические характеристики

1. Структура: ручной дозатор

2. Стандарт фланца дозатора: ANSI / BS4504 / GB;

3. Материал корпуса клапана: углеродистая сталь;

4. Материал вкладыша: резина;

5. Дозатор: стандартный из углеродистой стали (опционально из нержавеющей стали SS304);

6. Шаровой кран: стандартный латунный (опционально нержавеющая сталь SS304);

7. Предохранительный клапан: стандартный латунный (опционально нержавеющая сталь SS304);

8. Трубопроводная система: стандартная углеродистая сталь (опционально нержавеющая сталь SS304)

Сценарии применения

1. Взрывобезопасные зоны с высоким уровнем риска: резервуарная зона нефтеперерабатывающего завода, реактор химического завода, объекты хранения и транспортировки СПГ.

2. Требования к непрерывному подавлению пламени: пожар на нефтяном потоке (капсулированная подача жидкости обеспечивает непрерывное пенное покрытие в течение 30 мин+).

3. Коррозионная среда: морская платформа (корпус бака из 316SS устойчив к солевому туману), склад кислот (бутилкаучук устойчив к pH 1~13).

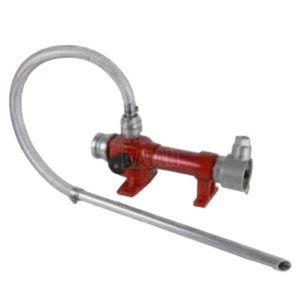

Принцип работы

Вода под давлением в противопожарной сети → Впрыск в резервуар для выдавливания капсулы → Количественный выход пенной жидкости → Пропорциональный смеситель → Генерирование смешанной жидкости 3%/6% → Устройство впрыска пены для подавления огня → Опорожнение капсулы → Автоматическое переключение на охлаждение чистой водой

Характеристики

1. Нулевое перекрестное загрязнение: Капсулы физически изолируют пенную жидкость и воду, чтобы избежать предварительного смешивания (срок годности пены увеличен ≥50%)

2. Сверхвысокая скорость опорожнения: Остаток пены ≤1% (скорость усадки капсулы ≥98%, что значительно превышает стандарт 85% для традиционных резервуаров под давлением)

3. Адаптация к экстремальным условиям

Температура: -40℃ ~ 120℃ (капсулы устойчивы к углеводородным растворителям)

4. Интеллектуальный мониторинг: магнитострикционный уровнемер + датчик давления (точность ±0.5%), связанный с системой BMS, сигнализация в реальном времени

5. Экономия на обслуживании: Срок службы капсул 10 лет (стоимость замены составляет всего 15% от перезагрузки резервуара)

Рабочее давление

1. Расчетное давление: 1,0~2,5 МПа

2. Давление разрыва капсулы: ≥3× рабочее давление (испытание ISO 1402)

3.Минимальное начальное давление 0,3 МПа (для обеспечения надежного срабатывания системы низкого расхода)

Оставьте свое сообщение