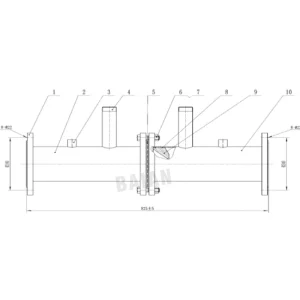

In-Line Foam Inductor Fixed Foam Proportioning Equipment

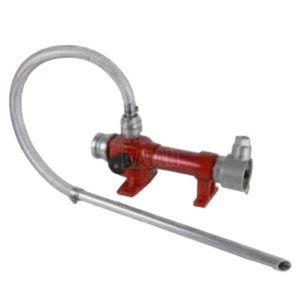

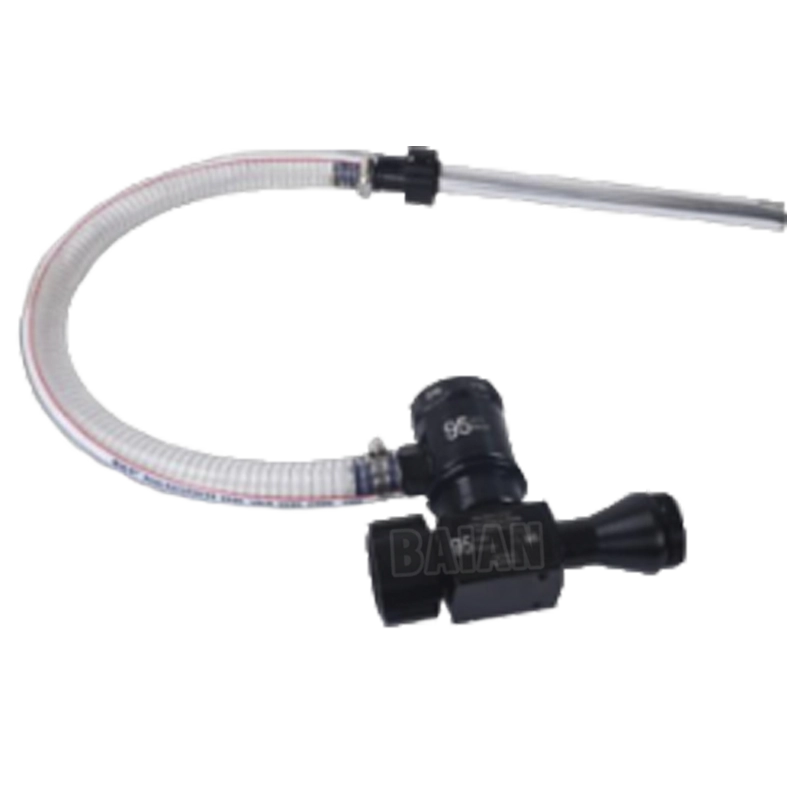

The In – Line Foam Inductor Fixed Foam Proportioning Equipment has a PVC suction hose, hard anodized aluminum main material and connectors like STORZ. For fixed small/medium foam systems, it uses hydraulic drive for 3%/6% mixing, offers flushing function, quick response (≤3s), passive design and 0.6 – 1.4MPa working pressure.

See more at Proportioning and Mixing Equipment catalog!

In-Line Foam Inductor Fixed Foam Proportioning Equipment

PHF/B

Specifications

1. Suction hose: PVC;

2. Main material: hard anodized aluminum;

3. Connectors: STORZ, NH, John Morris, GOST, Machino, etc.

Application scenarios

Suitable for fixed-installation small and medium-sized foam fire extinguishing systems:

Industrial facilities: local protection of small oil depots, chemical plants, and hazardous chemical warehouses;

Public buildings: airport hangars, parking lots, and tunnel fire protection systems;

Energy field: LNG filling stations, small storage tank areas;

Working principle

1. Hydraulic drive

2. Foam liquid suction

3. Instantaneous mixing

4. Proportional control: Lock the mixing ratio (such as 3%/6%) by adjusting the valve opening (manual or automatic)

Features

1. With flushing function, the nozzle can be cleaned;

2. Simple structure: no capsule/pressure tank, few failure points, low maintenance cost;

3. Quick response: ready to use, startup time ≤3 seconds;

4. Passive design: pure hydraulic mechanical structure, anti-electromagnetic interference, suitable for explosion-proof environment;

5. Space efficiency: direct pipeline connection, occupying more than 60% less space than tank equipment;

6. Wide compatibility: supports multiple types of sensor interfaces such as Pt/Ni/KTY, and can be connected to the fire control system.

Working pressure

0.6-1.4Mpa

Leave Your Message