H41X-16Q Flange Silencer Check Valve

The H41X-16Q Flange Silencer Check Valve is an automatic backflow prevention valve with a silencing design, offering ≤60dB noise and adjustable slow closing (1-10s) to reduce water hammer by 50%. Suitable for water supply, HVAC, and fire systems, it handles max 16 bar and 0°C-80°C.

See more at Check Valve Catalog!

H41X-16Q Flange Silencer Check Valve

PRODUCT DESCRIPTION

1.The flange silencer check valve is an automatic valve that automatically opens and closes the valve disc by the flow of the medium itself.

2. It is mainly used to prevent the medium from flowing back, to prevent the pump and the drive motor from reversing, and to control the release of the medium in the container.

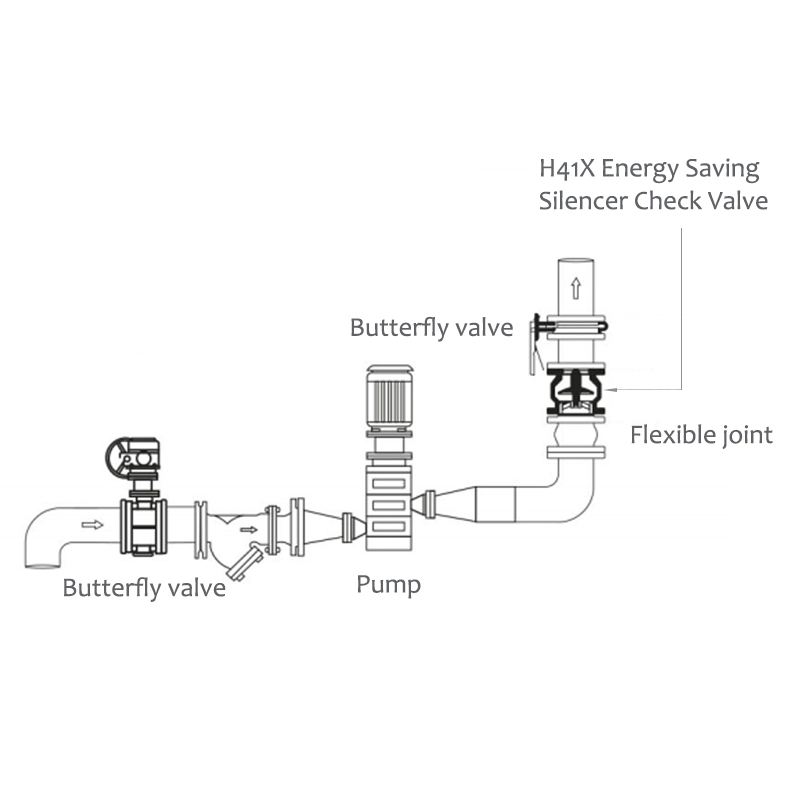

3.This valve is widely used in water supply and drainage systems, fire protection systems, HVAC systems and water pump outlets to prevent back flow from damaging the pump.

FEATURES

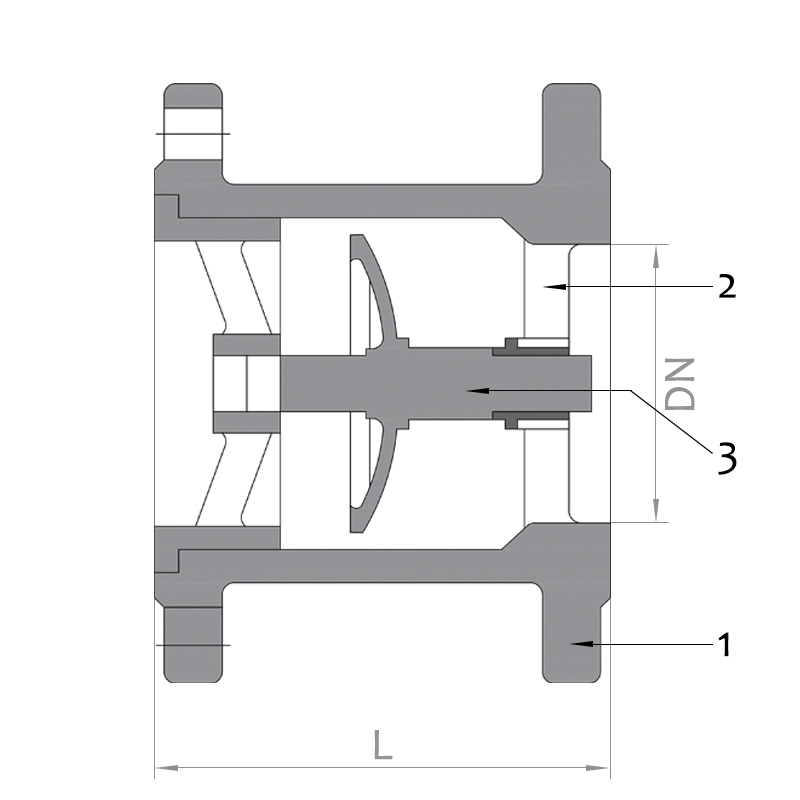

1.Check reliability Quick response to back flow, high sealing level (leakage rate ≤ 0.1%).

2.Low noise The silencing design makes the closing noise ≤ 60dB, suitable for quiet environments such as hospitals and residential areas.

3.Anti-water hammer The slow closing time is adjustable (1-10 seconds), which effectively reduces water hammer damage (pressure peak is reduced by more than 50%).

4.Low pressure loss Streamlined valve body design, resistance coefficient ≤ 0.5 when fully open.

APPLICATION

1.Building water supply and drainage: high-rise building water pump outlet, to prevent water hammer from damaging the pipe when the pump is stopped.

2.HVAC: chilled water circulation system, to reduce the noise of pump start and stop.

3.Fire protection system: protect fire pumps in the sprinkler network to avoid back flow and contamination of water sources.

4.Industrial circulating water: cooling water return pipeline, to reduce the impact of water hammer on the heat exchanger.

5.Municipal water supply: booster pump station outlet, to ensure stable operation of the network.

WORKING PRESSURE

Maximum working pressure 16 bar (230psi).

STANDARD

Product testing is carried out in accordance with GB/T13927 Industrial valve pressure test.

TEMPERATURE RANGE

0 °C to 80°C.

COATING

Fusion Bonded Epoxy Coating.

Leave Your Message