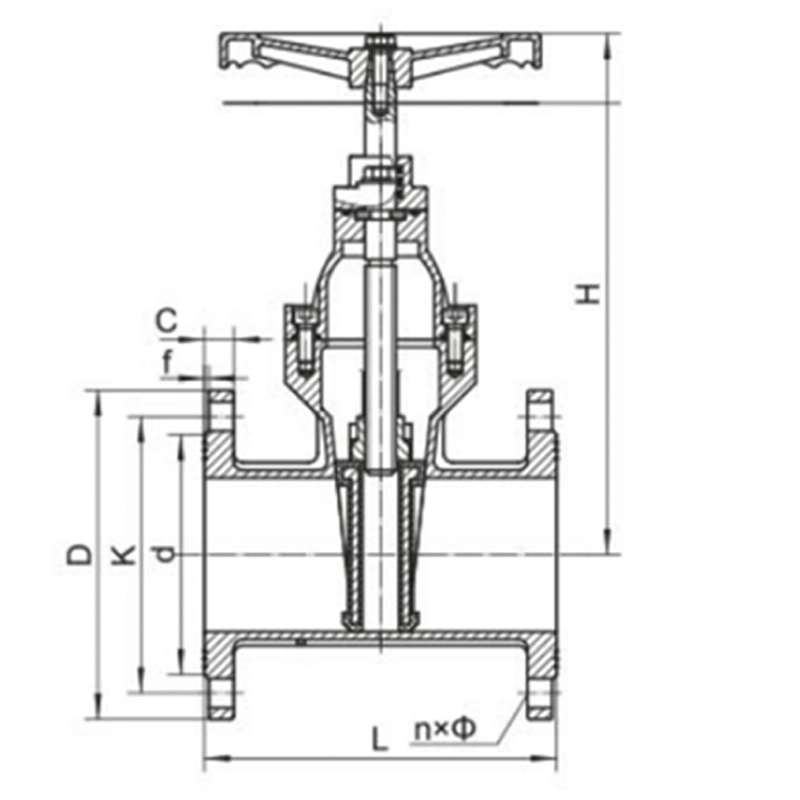

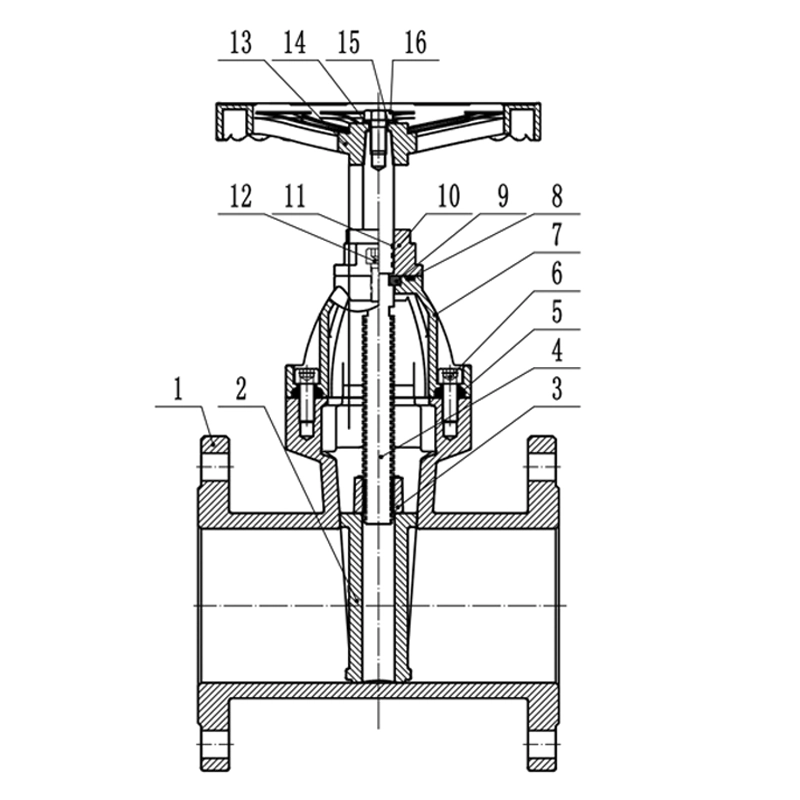

Válvula de gaveta de vedação resiliente Z45X-16Q sem fiação

O Non-Spring Resilient Seated Gate Valve solves traditional leakage and corrosion issues via a novel design with high-performance materials. Suitable for water, sewage, and chemical systems, it offers reliable sealing, easy maintenance, and operates at max 16 bar pressure with epoxy coating.

Ver o Válvula de gaveta Catálogo para mais informações!

Válvula de gaveta de vedação resiliente Z45X-16Q sem fiação

DESCRIÇÃO DO PRODUTO

1. a válvula de gaveta é uma das válvulas mais utilizadas em vários projectos de transporte de fluidos.

2. as válvulas de gaveta tradicionais geralmente têm o problema de fácil vazamento de fluido e corrosão grave das partes internas.

3. as válvulas de gaveta de vedação suave comuns no mercado são propensas a fugas na vedação do eixo da haste da válvula, e o anel de vedação não pode ser substituído sem interrupção da água e em qualquer abertura.

CARACTERÍSTICAS

1.The elastic seat seal gate valve adopts novel structural design, strict manufacturing technology and high-performance new materials to overcome the defects of poor sealing of traditional gate valves

2. fácil corrosão das partes internas, especialmente placas de portão, e fácil envelhecimento da fadiga elástica da borracha.

3. tem um desempenho de vedação fiável, operação leve, manutenção simples e conveniente, e longa vida útil.

4. é adequado para sistemas de água doméstica, sistemas de abastecimento e drenagem de água, sistemas de tratamento de esgotos, sistemas de transporte de fluidos químicos, etc.

CANDIDATURA

1. É utilizado como um dispositivo de corte na tubagem de fluido na construção.

2.proteção do ambiente urbano.

3. petroquímica.

4.Medicina.

5.Alimentos.

6. metalurgia.

7. têxteis.

8. energia e outras indústrias (não adequadas para estrangulamento).

PRESSÃO DE TRABALHO

Pressão máxima de trabalho 16 bar (230psi).

PADRÃO

O teste do produto é efectuado em conformidade com o teste de pressão da válvula industrial GB/T13927.

GAMA DE TEMPERATURAS

0 °C a 80°C.

REVESTIMENTO

Revestimento epóxi ligado por fusão.

Deixe a sua mensagem