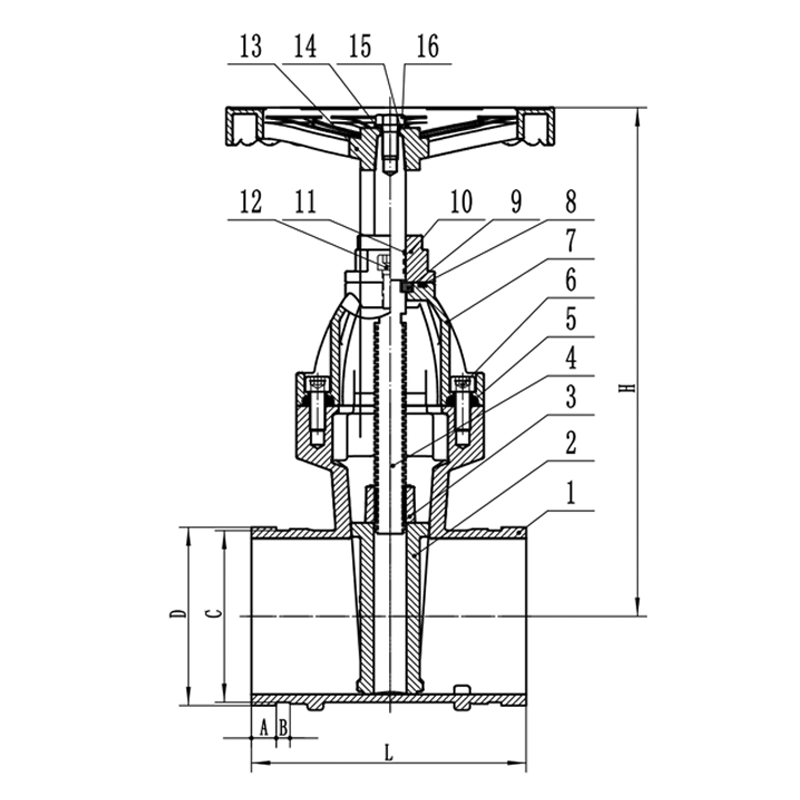

Z84X-16Q Задвижка с упругим уплотнением не поднимающегося типа с желобком

Сайт Задвижки с упругим уплотнением не восходящего типа Преодолевает традиционные проблемы протечек и коррозии благодаря новой конструкции с использованием высокоэффективных материалов. Подходит для водопроводных, канализационных и химических систем, имеет рифленые соединения, надежное уплотнение, простое обслуживание и работает при максимальном давлении 16 бар с эпоксидным покрытием.

См. Задвижка Каталог для получения дополнительной информации!

Z84X-16Q Задвижка с упругим уплотнением не поднимающегося типа

ОПИСАНИЕ ПРОДУКТА

1.Задвижка является одним из наиболее широко используемых клапанов в различных проектах по транспортировке жидкостей.

2.Традиционные задвижки обычно имеют проблему легкой утечки жидкости и серьезной коррозии внутренних деталей.

3.Распространенные на рынке задвижки с мягким уплотнением подвержены утечкам через уплотнение штока клапана, а уплотнительное кольцо не может быть заменено без перерыва подачи воды и при любом открытии.

ОСОБЕННОСТИ

1.Задвижка с эластичным уплотнением седла использует новую конструкцию, строгую технологию производства и высокопроизводительные новые материалы, чтобы преодолеть недостатки плохого уплотнения традиционных задвижек

2.Легкая коррозия внутренних частей, особенно пластин затвора, и легкое старение эластичной резины.

3.Он обладает надежной герметичностью, легким управлением, простым и удобным обслуживанием, а также длительным сроком службы.

4.Он подходит для систем бытового водоснабжения, систем водоснабжения и дренажа, систем очистки сточных вод, систем транспортировки химических жидкостей и т.д.

ПРИЛОЖЕНИЕ

1. Используется в качестве отсекающего устройства на трубопроводе для жидкости в строительстве.

2.защита городской среды.

3.Нефтехимия.

4.Медицина.

5.Еда.

6.Металлургия.

7.Текстиль.

8.Энергетика и другие отрасли (не подходит для дросселирования).

РАБОЧЕЕ ДАВЛЕНИЕ

Максимальное рабочее давление 16 бар (230psi).

СТАНДАРТ

Испытания продукции проводятся в соответствии с GB/T13927 Испытание промышленного клапана давлением.

ДИАПАЗОН ТЕМПЕРАТУР

От 0 °C до 80 °C.

ПОКРЫТИЕ

Эпоксидное покрытие с плавкой связью.

Оставьте свое сообщение