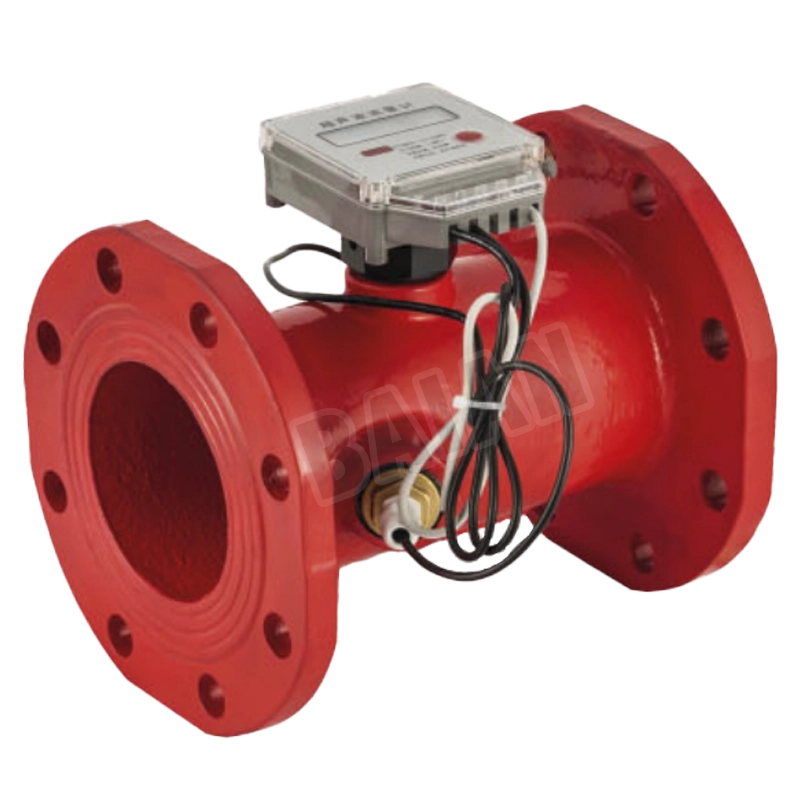

Расходомер фланцевого типа LWBT-16Q

The LWBT-16Q Flange Type Flow Meter uses ultrasonic technology to measure liquid flow, featuring a straight-through design for low pressure loss and suitability for fire protection and water supply systems at max 16 bar and 0°C-80°C.

См. подробнее Соединители и оборудование для контроля расхода Каталог!

Расходомер фланцевого типа LWBT-16Q

ОПИСАНИЕ ПРОДУКТА

1.The ultrasonic flow meter is a brand-new product, mainly used in liquid media such as fire protection pipes that need to measure flow.

2.The principle of the ultrasonic flow meter is to use the difference in propagation time of ultrasonic transducers sending and receiving ultrasonic waves in the downstream and upstream media to measure the flow velocity of the medium.

3.The ultrasonic velocity in the downstream direction will increase, and the ultrasonic velocity in the upstream direction will decrease.

4.The same propagation distance will have different propagation times.

5.According to this time, the flow velocity is obtained, and then the flow rate is calculated by the flow velocity.

ОСОБЕННОСТИ

1.The body of the ultrasonic flow meter is a straight-through integrated structure made of precision casting technology.

2.The hollow structure allows for truly unobstructed water flow, which is particularly suitable for China's heating water quality and working conditions, with less pressure loss.

3.The structure is simple, easy to install and maintain.

4.It is completely unaffected by impurities, chemicals and magnetic materials in the medium, and its operation is very stable and reliable.

5.The measuring structure has no moving parts, never wears out, and the measurement accuracy is not affected by the use cycle.

6.It uses a single-chip microcomputer imported from the United States and an advanced micro-power design. It can be powered by batteries only.

7.It uses a special ultrasonic detection chip imported from Germany, which has higher accuracy.

8.It can be installed horizontally or vertically, which is extremely convenient and practical.

Приложение

1. Система противопожарной защиты: защита спринклерных труб, пожарных гидрантов и т.д. от гидроударов и перепадов давления.

2.Система водоснабжения и водоотведения: предотвращение избыточного давления, вызванного запуском и остановкой насоса или неправильной работой клапана.

3.Промышленный трубопровод: защита сосудов под давлением или трубопроводов в области химии, ОВКВ, энергетики и т.д.

4.Высотные здания: сбалансируйте разницу давления воды между этажами, чтобы избежать разрыва трубопровода.

Installation precautions

1.Before installation, the pipeline system should be thoroughly cleaned to remove debris such as hemp, sand and stones in the branch pipe to avoid meter failure.

2.It can be installed horizontally or vertically. In order to facilitate the over-standard display window, the position can be adjusted according to the installation situation. The water flow direction should be consistent with the arrow mark on the meter.

3.The diameter of the front and rear pipes must match the diameter of the meter.

4.Dirt filters and shut-off valves should be placed at both ends to facilitate filtering of dirt and maintenance and replacement

РАБОЧЕЕ ДАВЛЕНИЕ

Максимальное рабочее давление 16 бар (230psi).

СТАНДАРТ

Испытания продукции проводятся в соответствии с GB/T13927 Испытание промышленного клапана давлением.

ДИАПАЗОН ТЕМПЕРАТУР

От 0 °C до 80 °C.

ПОКРЫТИЕ

Эпоксидное покрытие с плавкой связью.

Оставьте свое сообщение