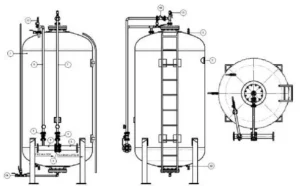

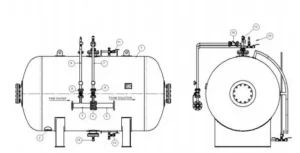

Foam Bladder Tank

Material: carbon steel

Color: Red

Applicable foam type: All

Maximum flow range: 114-18000LPM

Maximum capacity range: 25 Gallon to 5000 Gallon

Largest Range of Ratio Controllers: 50NB/80NB/100NB

Характеристики

2.Largest Range of Capacities (25 Gallon to 4000 Gallon)in Vertical & Horizontal Mounting.

3.Largest Range of Ratio Controllers 50NB/80NB/100NB.

4.Wildest Flow Range (114-18000 LPM).

5.Lowest Proportioning Losses.

6.Nylon reinforced nitrile foam bladder is UL Listed with AFFF & AR-AFFF Foam.

7.Concentrate & compatible with all types of foam Concentrates.

8.High reliability and design simplicity minimizes chances of system failure.

9.Manual/ automatic operation.

10.Horizontal/ Vertical Mounting.

11.Low Installation Cost.

12.Can be adapted into existing foam system.

Benefits

2.Easy retrofit of existing fire protection systems can reduce expensive redesign and refitting.

3.Automatic or manual operation is available.

4.The unit is adaptable to nearly all types of fixed fire protection systems.

5.Design simplicity minimizes chance of system failure.

6.Valves are quick opening.

7.The construction of the EuroSafe Balanced Pressure Proportioning System provides that there is no dilution of the concentrate that is not used after activation of the system.

Приложение

1.Flammable liquid storage tanks in refineries and petrochemical units.

2.Chemical process plants.

3.Air- craft hangars.

4.Oil Jetties.

5.Loading and unloading gantries.

6.Off- Shores Platforms.

7.Warehouses.

8.Foam application through spray nozzle and foam sprinkler.

Operation

1.During operation, water is charged between the foam vessel and the foam bladder, thereby causing the pressurization of foam concentrate stored inside the foam bladder to a pressure, as that of fire water supply.

2.The Foam Concentrate is injected in the fire- water stream due to pressure drop at the foam proportioner. Foam proportioner provides accurate and automatic proportioning of foam concentrate within its flow range with very low proportioning losses.

Specification

Foam vessel is designed and fabricated to ASME Sec. VIII Div. for a maximum working pressure of12.06 Bar and Hydro tested to a pressure of 18.09 Bar. Internal surface is coated with coal tar epoxy and external surface with fire –res epoxy paint. Lifting lugs are welded to the vessel. Vertical Vessel is provided with legs supports and horizontal vessel with saddle supports. Anchoring holes are drilled in the base plate of supports. Anchor bolts are also supplied with the unit. Foam Bladder is made of Nylon reinforced nitrile rubber, which is fixed inside the vessel.

Оставьте свое сообщение