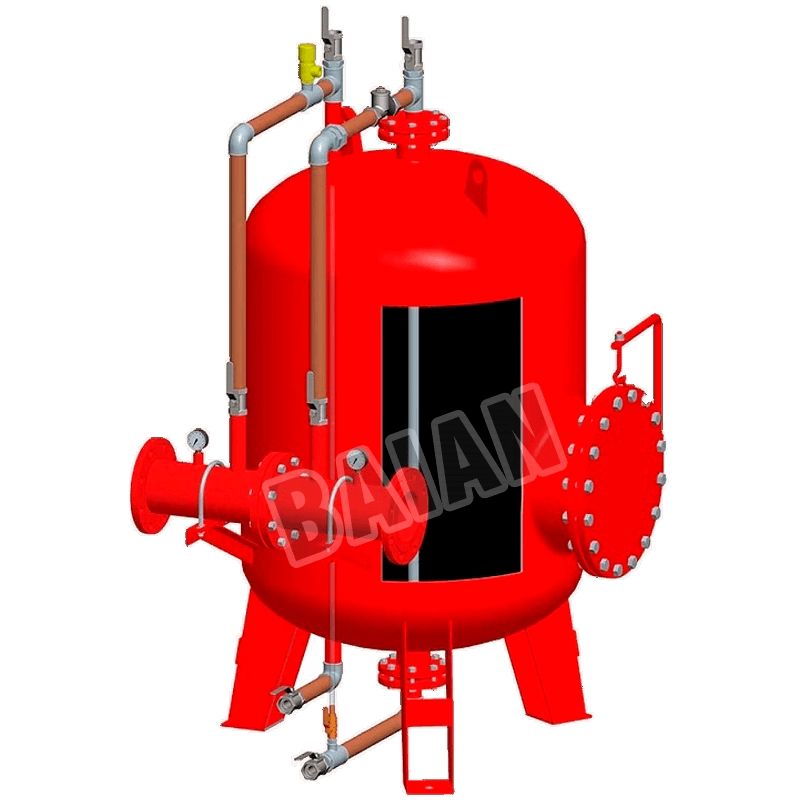

Tanque fixo com bexiga de espuma Tipo vertical

Manually operated, this Foam storage equipment features ANSI/BS4504/GB flanges. The valve body is carbon steel with a rubber liner. Components like the proportioner, ball valve, safety valve, and pipeline system are standard carbon steel (SS304 optional).

Tanque fixo com bexiga de espuma Tipo vertical

Especificações

1. Operation: Manual

2. Norma da flange do doseador: ANSI / BS4504 / GB;

3. Material do corpo da válvula: aço-carbono;

4. Material do forro: borracha;

5. Proporcionador: aço carbono normalizado (aço inoxidável SS304 opcional);

6. Válvula de esfera: latão normal (aço inoxidável SS304 opcional);

7. Válvula de segurança: latão normal (aço inoxidável SS304 opcional);

8. Sistema de tubagem: aço carbono normalizado (aço inoxidável SS304 opcional);

Cenários de aplicação

1. Foam fire extinguishing system: protect Class B fire high-risk areas such as oil depots, chemical plants, and airport fuel depots.

2. Space-constrained scenarios: vertical design saves floor space (40% less space than horizontal).

3. Anti-cross contamination: The capsule physically isolates the foam liquid from water to avoid premix failure.

Princípio de funcionamento

1. Water injection and pressurization: Fire water is injected into the outer cavity of the capsule → squeezes the foam liquid in the capsule.

2. Quantitative delivery: The foam liquid is squeezed out to the proportion mixer (such as 3%/6% concentration) → mixed with water flow and sprayed.

3. Automatic switching: After the capsule is emptied, the water flow is directly output (the system seamlessly switches to pure water fire extinguishing).

Caraterísticas

1. Zero residue design: Capsule shrinkage rate > 95%, foam liquid utilization rate is extremely high (residue < 1%).

2. Visual monitoring: liquid level gauge + pressure gauge dual indication (pressure drop alarm when the capsule ruptures).

3. Fast filling: reserve the foam liquid injection port, replenishment does not need to empty the system.

Pressão de trabalho

1. Design pressure: 1.0~1.6 MPa (in accordance with NFPA 11 standards), bursting pressure ≥ 3 times the working pressure.

2. Capsule pressure resistance: 0.3~1.2 MPa (low pressure start, high pressure seal anti-leakage).

Deixe a sua mensagem