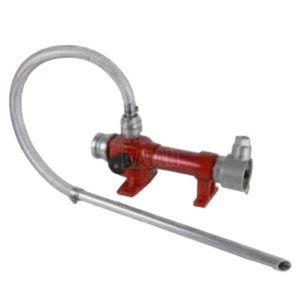

Tanque fixo com bexiga de espuma Vertical

With ANSI/BS4504/GB flanges, this Equipamento de armazenamento de espuma has a carbon steel valve body and rubber liner. Components (proportioner, valves, pipeline) are standard carbon steel/brass (SS304 optional) with a solenoid valve.

Tanque fixo com bexiga de espuma Vertical

Especificações

1. Proportional flange standard: ANSI / BS4504 / GB;

2. Valve body material: carbon steel;

3. Liner material: rubber;

4. Proportional: standard carbon steel (SS304 stainless steel optional);

5. Ball valve: standard brass (SS304 stainless steel optional);

6. Safety valve: standard brass (SS304 stainless steel optional);

7. Pipeline system: standard carbon steel (SS304 stainless steel optional)

8. Structure: electronic with solenoid valve

Aplicação

1. High-risk Class B fire: oil tank area, chemical warehouse, aviation fuel depot.

2. Space-sensitive scenarios: vertical occupancy is only 60% of horizontal (such as ship engine room, underground pump room).

3. Anti-pollution system: capsules physically isolate foam liquid and water to prevent premixed degradation (applicable to AFFF/AR-AFFF).

Princípio de funcionamento

Fire water → squeeze capsule wall → quantitative output of foam liquid → proportion mixer (3%/6%) → foam injection system → capsule emptying → automatic switching to pure water mode

Caraterísticas

1. Capsule sealing (working pressure 0.3~1.2 MPa, leakage rate <0.1%/year)

2. Foam residual rate ≤1% (capsule shrinkage ratio >95%)

3. Temperature adaptability (-40°C~80°C)

3. When the capsule ruptures, the water flows directly through the sprinkler system (no risk of interruption)

4. Life cycle: tank ≥20 years, capsule 10 years (2-year hydraulic test required)

Pressão de trabalho

1. Design pressure: 1.0~1.6 MPa (in compliance with NFPA 11 bursting pressure ≥3 times).

2. Capsule pressure resistance: 0.3~1.2 MPa (low-pressure start-up to prevent bursting, high-pressure sealing to prevent leakage).

3. Test standard: Capsules are tested according to ISO 1402:2009 hydraulic pressure test (1.5 times the pressure for 30 minutes).

Deixe a sua mensagem