Clapet anti-retour à clapet en caoutchouc de type rainuré H84X-16

The H84X-16 Grooved Type Rubber Flap Check Valve uses a grooved clamp for quick installation, with a rubber disc ensuring tight sealing and low water hammer. Suitable for sewage, chemical, and water supply systems, it handles max 16 bar pressure and 0°C-80°C, preventing backflow efficiently.

En savoir plus Clapet anti-retour Catalogue !

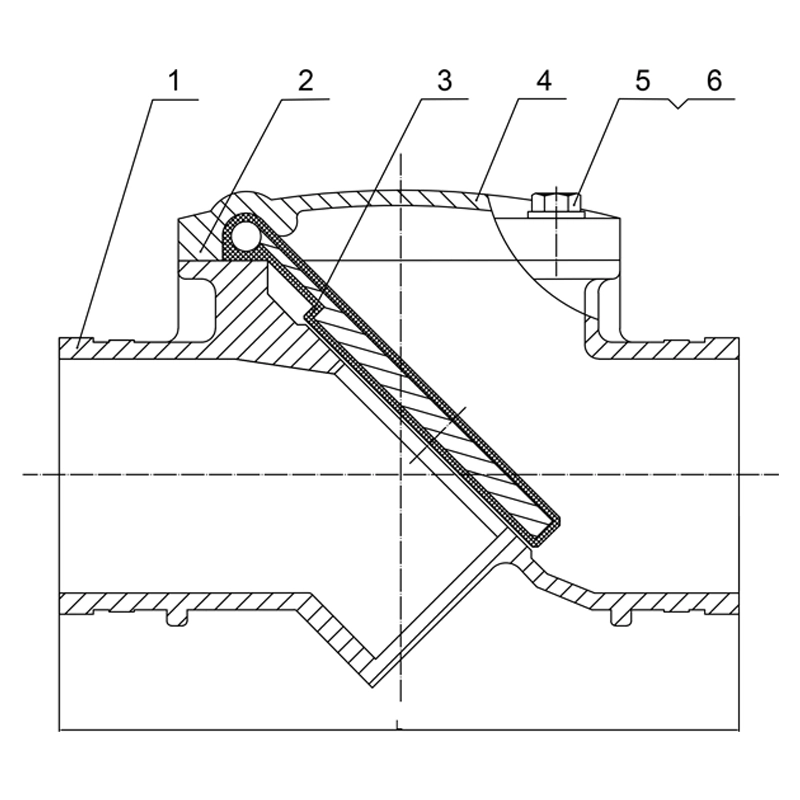

Clapet anti-retour à clapet en caoutchouc de type rainuré H84X-16

DESCRIPTION DU PRODUIT

1.The grooved rubber disc check valve is a valve that is quickly connected through a grooved clamp.

2.It mainly uses the automatic opening and closing function of the rubber disc (flexible seal) to prevent the medium in the pipeline from flowing back.

3.It is a type of one-way valve.

4.Forward flow: The medium pressure pushes the rubber valve disc to open, allowing the fluid to pass.

5.Reverse flow: When the medium flows in the opposite direction, the valve disc automatically closes under the action of gravity or back pressure, sealing and blocking the flow.

CARACTÉRISTIQUES

1.Quick installation:Adopt groove clamp connection, saving welding or flange docking time, suitable for projects with tight schedule.

2.Low water resistance design:The valve disc is light, with a large opening angle, reducing fluid resistance and significant energy saving effect.

3.Strong sealing:The rubber valve disc fits the valve seat flexibly, adapts to certain particulate impurities, and has a better sealing effect than metal hard seal.

4.Corrosion resistance:The valve body is lined with rubber or corrosion-resistant materials, suitable for sewage, acid and alkali medium environment.

5.Easy maintenance:Simple structure, the valve disc can be replaced by removing the clamp without stopping the entire system

CANDIDATURE

1.Water supply and drainage system:Municipal water supply network, fire protection pipeline, to prevent water hammer impact when the water pump stops.

2.Industrial pipeline:Corrosive medium transmission pipeline in chemical and pharmaceutical plants.

3.Construction field:Secondary water supply and air conditioning circulating water system for high-rise buildings.

4.Sewage treatment:Sewage recycling pipeline containing particles and sludge, strong resistance to impurities

PRESSION DE SERVICE

Pression de service maximale de 16 bars (230psi).

STANDARD

Les tests de produits sont effectués conformément à la norme GB/T13927 sur les tests de pression des vannes industrielles.

PLAGE DE TEMPÉRATURE

0 °C à 80 °C.

REVÊTEMENT

Revêtement époxydique fusionné.

Laissez votre message