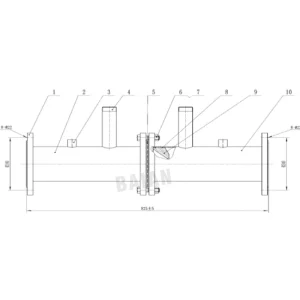

Réservoir à vessie de mousse fixe Type horizontal

Le Réservoir à vessie de mousse fixe Type horizontal features a manual structure, proportioner flange to ANSI/BS4504/GB standards, carbon steel valve body with rubber liner, and carbon steel proportioner, ball valve, safety valve, and pipeline system (SS304 stainless steel optional for all).

En savoir plus Équipement de stockage de mousse Catalogue !

Réservoir à vessie de mousse fixe Type horizontal

Spécifications

1. Structure: Manual

2. Proportioner flange standard: ANSI / BS4504 / GB;

3. Valve body material: carbon steel;

4. Liner material: rubber;

5. Proportioner: standard carbon steel (SS304 stainless steel optional);

6. Ball valve: standard brass (SS304 stainless steel optional);

7. Safety valve: standard brass (SS304 stainless steel optional);

8. Pipeline system: standard carbon steel (SS304 stainless steel optional);

Scénarios d'application

1. Large flow suppression system: petrochemical storage tank fire embankment, airport fuel depot (single tank liquid supply ≥50,000L).

2. Low space deployment: height ≤2.5m (suitable for height-restricted plant/tunnel fire protection).

3. Earthquake-prone areas: horizontal low center of gravity design (certified by IBC 2018 Seismic Design Category D).

Principe de fonctionnement

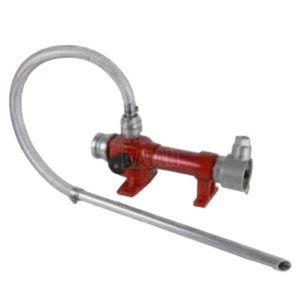

Pressure fire water → Inject into the tank from the end → Uniformly squeeze the capsule → Zero residual output of foam liquid → Proportional mixer (3%/6%) → Cover the burning liquid surface to suffocate the fire

Caractéristiques

1. Seismic stability

2. Ultra-large capacity support

3. Convenient maintenance

4. Mixing efficiency

Pression de service

1. Design pressure: 1.0~1.6 MP (PN16)

2. Capsule working pressure: 0.3~1.2MPa

Laissez votre message