Fine Mist Nozzle

Material:stainless steel

Color:Gray

Fine Mist Nozzle

Description

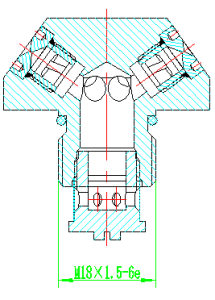

The fine mist nozzle is made of high-precision austenitic stainless steel. It consists of the main body, nozzle, and filter

screen, with its core components being multiple nozzles with a special structure mounted on the conical surface of the main body. Water under a certain pressure enters the nozzle through the filter screen and is ejected at high speed from the nozzle holes, creating strong friction with the surrounding air, which tears the water flow to form fine mist that is ejected at a certain angle. The fine mist ejected by this high-pressure fine mist nozzle belongs to Class I fine mist, with Dv0.5 < 65μm and Dv0.99 < 100μm. It has high pressure and good dispersal effect, with a long retention time of the mist after spraying, and compared to other nozzles, it can reduce the intensity of spray for fire extinguishing and controlling, while using less water.

Technical parameters

When the nozzle is installed under the ceiling, you can optionally install a decorative cover for the nozzle. Pre-drill a Φ30 hole in the ceiling and ensure that the end of the fine mist pipe is approximately 40mm away from the bottom of the ceiling. When welding the nozzle which occupies the connector, put on the decorative cover.

Installation Instructions

1.Choose the nozzle based on the height, area, fire type, shape of the protected objects, and type of fire suppression system in the protective area. The selection of the nozzle should also consider the following technical parameters: ① applicable range; ② flow characteristics of the nozzle; ③ maximum height of the protected space; ④ maximum distance from the nozzle to the protected object; ⑤ maximum and minimum spacing between nozzles; ⑥ maximum protected area for each nozzle; ⑦ maximum distance from the nozzle to the wall; ⑧ maximum and minimum working pressure of the nozzle.

Laissez votre message