100X-16Q Valve flottante

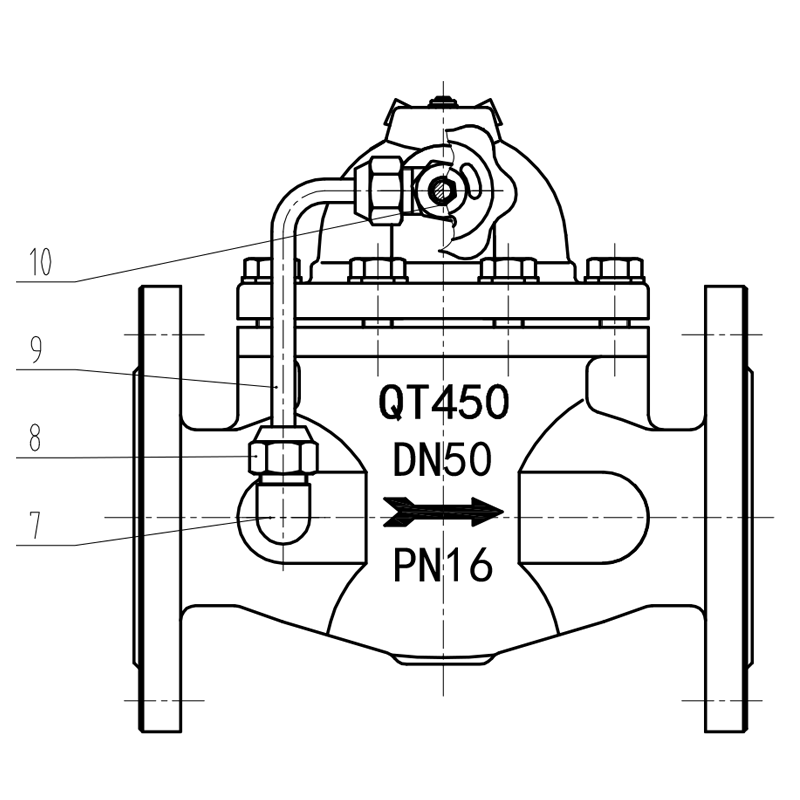

Le 100X - 16Q Soupape flottante contrôle automatiquement le niveau de liquide à l'aide d'un flotteur et de signaux à distance, convient pour les réservoirs et les piscines. Doté de deux modes de contrôle et d'un réglage précis, il fonctionne à une pression maximale de 16 bars et à une température comprise entre 0 et 80 °C.

En savoir plus Valve de contrôle Catalogue !

100X-16Q Valve flottante

CARACTÉRISTIQUES TECHNIQUES

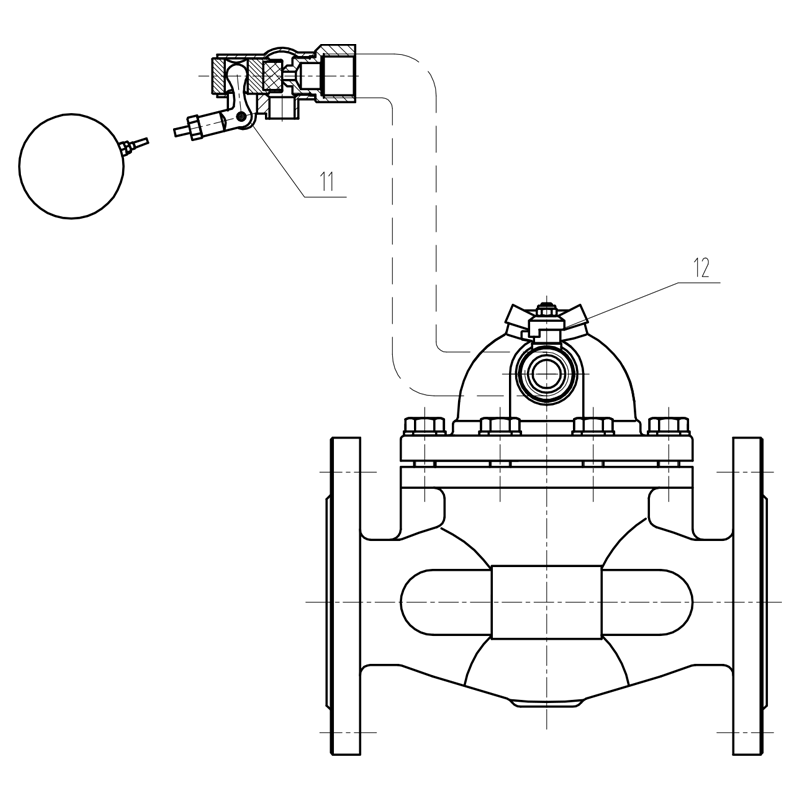

1. la vanne à flotteur est une vanne qui peut s'ouvrir et se fermer automatiquement en détectant la variation du niveau de liquide par l'intermédiaire d'un flotteur et en l'associant à un signal de commande à distance.

2. il est principalement utilisé pour contrôler le niveau de liquide dans les installations de stockage d'eau telles que les réservoirs d'eau et les piscines, et possède des fonctions de rétroaction mécanique et d'opération à distance.

3. le niveau de liquide augmente : Le flotteur monte avec le niveau d'eau, déclenche le signal de fermeture par le levier, la vanne se ferme progressivement et l'arrivée d'eau s'arrête.

4. le niveau de liquide baisse : Le flotteur descend, le levier déclenche le signal d'ouverture, la vanne s'ouvre et la réalimentation en eau commence.

ARTICLE :

1) Double mode de contrôle : permet le contrôle automatique du flotteur mécanique et le contrôle électronique à distance pour répondre à des conditions de travail complexes.

2. réglage précis du niveau de liquide : les seuils de niveau de liquide haut et bas peuvent être réglés pour obtenir un démarrage et un arrêt précis, évitant le débordement ou la marche à vide.

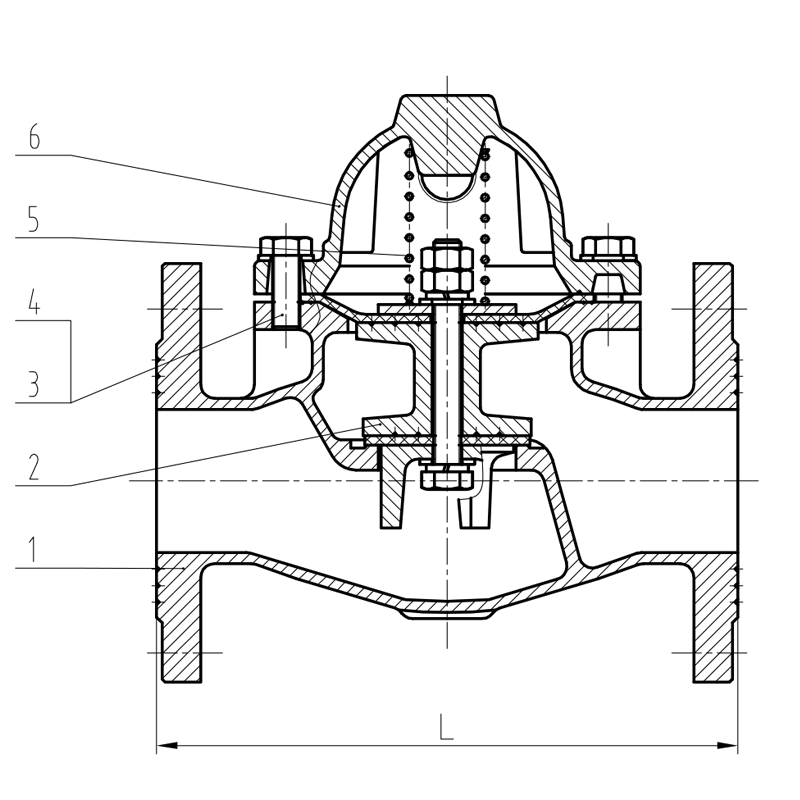

3. étanchéité élevée : le siège de la vanne adopte un joint souple (tel que le caoutchouc EPDM), qui est étanche et résistant à l'usure lorsqu'il est fermé.

4. forte anti-interférence : le mécanisme du flotteur et l'actionneur sont séparés pour réduire l'impact des impuretés de l'eau sur la précision du contrôle.

5) Faible coût de maintenance : structure modulaire, l'actionneur ou le flotteur peuvent être remplacés séparément en cas de défaillance.

Scénarios d'application typiques

1) Système d'approvisionnement en eau : réapprovisionnement automatique en eau et protection du niveau de liquide pour les réservoirs d'eau en toiture et les réservoirs d'eau souterrains.

2) Système de protection contre l'incendie : contrôle du niveau d'eau des réservoirs d'eau d'incendie pour assurer des réserves d'eau d'urgence.

3. eau de circulation industrielle : régulation du débit et gestion des économies d'énergie des tours de refroidissement et des systèmes de réalimentation en eau des chaudières.

4. irrigation agricole : contrôle intelligent du niveau d'eau des grands réservoirs de stockage afin de réduire les interventions manuelles.

PRESSION DE SERVICE

Pression de service maximale de 16 bars (230psi).

STANDARD

Les tests de produits sont effectués conformément à la norme GB/T13927 sur les tests de pression des vannes industrielles.

PLAGE DE TEMPÉRATURE

0 °C à 80 °C.

REVÊTEMENT

Revêtement époxydique fusionné.

Laissez votre message