H81X-16Q Válvula de retención de silenciador tipo ranurado

El H81X-16Q Válvula antirretorno de silenciador tipo ranurado combina conexiones ranuradas con silenciamiento y prevención del reflujo. Su diseño de cierre lento reduce los golpes de ariete y el ruido (<=60dB), adecuado para HVAC, protección contra incendios y sistemas de suministro de agua con una presión máxima de 16 bares y un rango de 0°C-80°C.

Más información en Válvula de retención ¡Catálogo!

H81X-16Q Válvula de retención de silenciador tipo ranurado

DESCRIPCIÓN DEL PRODUCTO

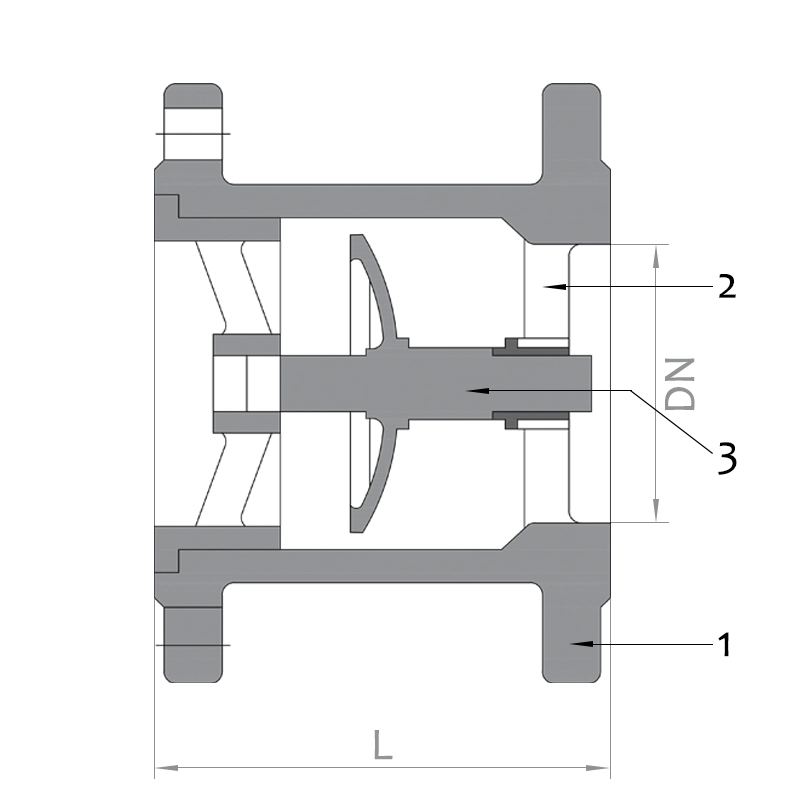

1.La válvula de retención silenciosa ranurada es una válvula especial que combina el método de conexión ranurada, la función de silenciador y la función de retención.

2.Se utiliza principalmente en sistemas de tuberías para evitar el reflujo del medio.

3.Reduce el impacto del golpe de ariete y reduce el ruido cuando la válvula está cerrada.

CARACTERÍSTICAS

1.Conexión de ranura:Se adopta la conexión de ranura tipo abrazadera, y no se requiere soldadura ni procesamiento de roscas durante la instalación. Se fija mediante anillos de sellado de goma y abrazaderas, lo que simplifica la construcción y facilita el mantenimiento.

2..Diseño silencioso:Estructura de cierre lento: Cuando el disco de la válvula se cierra, lo hace lentamente a través de resortes, amortiguación hidráulica o mecanismos de palanca para evitar el ruido de impacto causado por el cierre instantáneo de las válvulas de retención tradicionales.

3.Optimización del canal de flujo: El diseño aerodinámico del interior del cuerpo de la válvula reduce las turbulencias y el ruido de las vibraciones.

4.Check function:El disco de la válvula se abre por la presión de flujo hacia adelante del medio, y se cierra automáticamente cuando el medio se invierte para evitar el reflujo.

5.Poco ruido: El diseño de cierre lento reduce significativamente el "efecto de golpe de ariete" y el ruido de impacto del cierre de la válvula, y es adecuado para entornos sensibles al ruido (como hospitales y zonas residenciales).

6.Fácil instalación: La conexión de ranura ahorra horas de mano de obra y es especialmente adecuada para proyectos de renovación o lugares con espacio limitado.

7.Durabilidad: El disco de la válvula está hecho principalmente de acero inoxidable o aleación de cobre, y el material de sellado es caucho de nitrilo o EPDM, que es resistente a la corrosión y tiene una larga vida útil.

8.Mantenimiento sencillo: La estructura desmontable es conveniente para limpiar las impurezas de la tubería o sustituir las juntas.

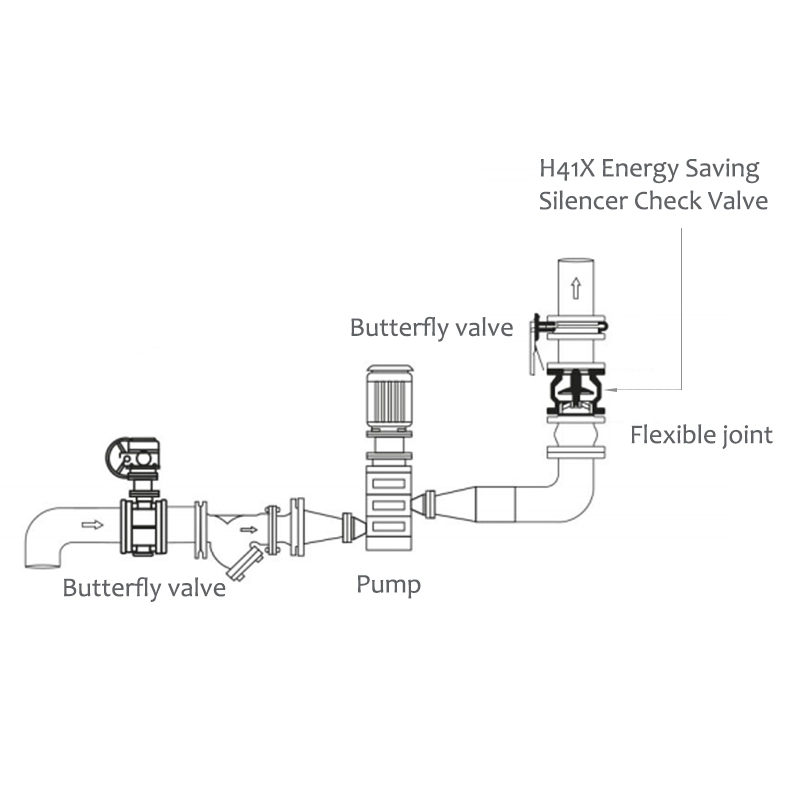

SOLICITUD

1.Suministro de agua y drenaje del edificio: salida de la bomba de agua del edificio de gran altura, para evitar que el golpe de ariete dañe la tubería cuando se detiene la bomba.

2.HVAC: sistema de circulación de agua fría, para reducir el ruido de arranque y parada de la bomba.

3.Sistema de protección contra incendios: proteger las bombas contra incendios de la red de rociadores para evitar el reflujo y la contaminación de las fuentes de agua.

4.Agua de circulación industrial: tubería de retorno del agua de refrigeración, para reducir el impacto del golpe de ariete en el intercambiador de calor.

5.Suministro municipal de agua: salida de la estación de bombeo de refuerzo, para garantizar el funcionamiento estable de la red.

PRESIÓN DE TRABAJO

Presión máxima de trabajo 16 bar (230 psi).

ESTÁNDAR

Las pruebas de los productos se realizan de acuerdo con la norma GB/T13927 Prueba de presión de válvulas industriales.

RANGO DE TEMPERATURA

0 °C a 80°C.

REVESTIMIENTO

Revestimiento epoxi unido por fusión.

Deje su mensaje