Filtro tipo T fabricado LX-16Q

The LX-16Q Fabricated T Type Strainer is a mechanical device with a T-shaped structure, intercepting solid particles in pipelines. Offering low pressure loss, high dirt capacity, and easy maintenance, it suits liquids/gases, with max 16 bar pressure and 0°C-80°C range.

Ver mais em Válvula de filtragem Catálogo!

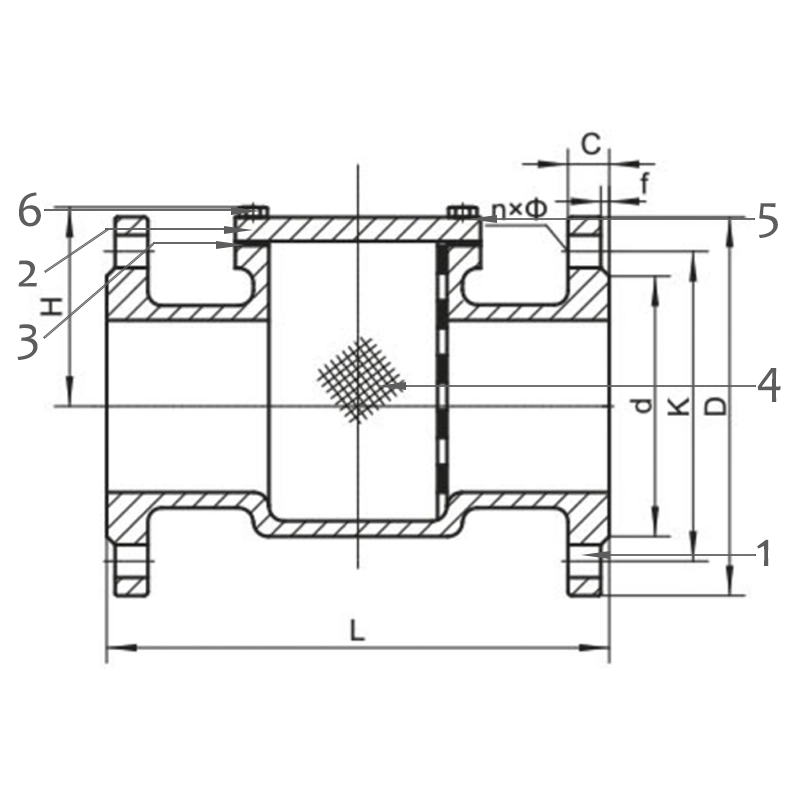

LX-16Q Fabricated T Type Strainer

DESCRIÇÃO DO PRODUTO

1.T-type Strainer (also known as T-type pipe filter) is a filtering device that intercepts solid particles in the pipeline through a T-shaped structure and a built-in filter.

2.It is a mechanical filter.

3.Its name comes from the shape of the shell that resembles the letter "T".

4.The horizontal inlet and outlet are located on the same axis, and the vertical direction is the filter chamber, which is convenient for the filter to be disassembled and washed.

5.The main function is to protect downstream equipment such as valves, pumps, and instruments from damage by impurities.

CARACTERÍSTICAS

1.Low pressure loss Straight-through flow channel design, full-diameter filter reduces fluid resistance (initial pressure drop ≤ 0.05MPa).

2.High dirt holding capacity Large filter chamber can accommodate more impurities and extend maintenance cycle.

3.Convenient maintenance Vertical chamber cover design, filter can be cleaned without disassembling the pipeline (some models support online cleaning).

4.Applicable media Liquid (water, oil, chemical fluid), gas (steam, compressed air) and gas-liquid mixed media.

5.Pressure and temperature resistance Maximum pressure resistance PN40 (stainless steel shell), temperature range: -0℃~80℃

CANDIDATURA

1.Industrial pipelines: protect centrifugal pumps, control valves, and flow meters from damage caused by welding slag and rust particles.

2.Energy system: filter condensate impurities in steam pipe networks to extend the life of steam traps.

3.Water treatment: raw water pretreatment and suspended solids interception in circulating water systems.

4.Food and pharmaceuticals: process fluid filtration (sanitary stainless steel 316L material is required).

5.Petrochemical industry: separate solid particles in oil pipelines to prevent equipment wear

PRESSÃO DE TRABALHO

Pressão máxima de trabalho 16 bar (230psi).

PADRÃO

O teste do produto é efectuado em conformidade com o teste de pressão da válvula industrial GB/T13927.

GAMA DE TEMPERATURAS

0 °C a 80°C.

REVESTIMENTO

Revestimento epóxi ligado por fusão.

Deixe a sua mensagem