Vertical multi-stage fire pump unit

Vertical multi-stage fire pump unit

Presentación del producto

1.Vertical multi-stage fire pump units and vertical multi-stage fire-stressing pump units are designed in accordance with the Fire Pump Standard of the People's Republic of China (GB6245-2006) (Fire Pump Performance Requirements and Test Methods). Combining our company's years of production experience with reference to leading modern hydraulic models, these centrifugal pumps are specifically designed for fire protection systems. Their performance reaches the advanced level of similar domestic products. Type testing by the National Fire Equipment Quality Supervision and Inspection Center has confirmed that all performance indicators meet standard requirements, earning them the "Fire Product Certification Certificate" issued by the Fire Product Conformity Assessment Center of the Ministry of Emergency Management.

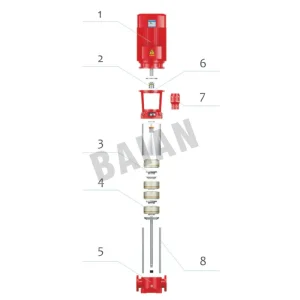

2.Vertical Structure: This pump features a vertical, multi-stage, segmented design. The inlet and outlet flanges are aligned horizontally and have the same diameter, facilitating pipe connections and extremely easy assembly and disassembly.

3.Hydraulic Balance: The impeller is hydraulically balanced to counteract axial forces. A guide bearing is located at the lower end of the pump, and the shaft is secured to the motor shaft via a clamping coupling. The outer shell is a stainless steel cylinder.

4.Reliable Sealing: The shaft seal utilizes a carbide mechanical seal, ensuring leak-free and shaft-free wear, ensuring a clean working environment.

5.Extended Service Life: The impeller and rotating friction parts are made of corrosion-resistant alloy, preventing rust and clogging firefighting equipment such as sprinklers, thereby extending the pump's service life.

6.Hydraulic Balance: The CDL vertical multi-stage firefighting pressure-stabilizing pump rotates counterclockwise when viewed from the motor end. The GDL vertical multi-stage firefighting pump rotates clockwise when viewed from the motor end.

Core Advantages

1.Fully Electric Protection

Prevents impacts during production and protects the stator coils

2.High-performance design, no burnout

Built-in overload protection and phase loss protection prevent burnout

3.Long-lasting durability

Long bearing life, low noise, and energy savings

4.Excellent heat dissipation

Full contact between the core and the casing ensures excellent heat dissipation and low operating temperature rise.

Aplicaciones

Primarily used for pressurized water supply in fire protection systems. Also suitable for industrial and urban water supply and drainage, pressurized water supply in high-rise buildings, long-distance water supply, heating systems, bathrooms, boiler hot and cold water circulation, water supply in air conditioning and refrigeration systems, and supporting equipment.

Especificaciones

1.Flow Rate Range: 1-500 L/s

2.Lift Range: 30-220 m

3.Power Range: 0.75-160 kW

4.Rated Speed: 2900 r/min, 2850 r/min

Operating Conditions

1.Media Temperature: -15°C to 80°C

2.Ambient temperature not exceeding 40°C, relative humidity less than 95%. Suitable for conveying clear water or non-corrosive media with similar physical and chemical properties to clear water, with a solid insoluble content not exceeding 0.1%.

Structural Analysis

Deje su mensaje