H44X-16Q Válvula antirretorno de clapeta de goma

El GL83H-16Q Filtro ranurado tipo Y es un filtro de tuberías en forma de Y con conexiones ranuradas, diseñado para eliminar impurezas en agua, vapor o gas. Con baja resistencia al flujo y limpieza en línea, ofrece una presión máxima de 16 bares y compatibilidad con temperaturas de 0 °C a 80 °C para diversos sistemas industriales.

Más información en Válvula de retención ¡Catálogo!

H44X-16Q Válvula antirretorno de clapeta de goma

DESCRIPCIÓN DEL PRODUCTO

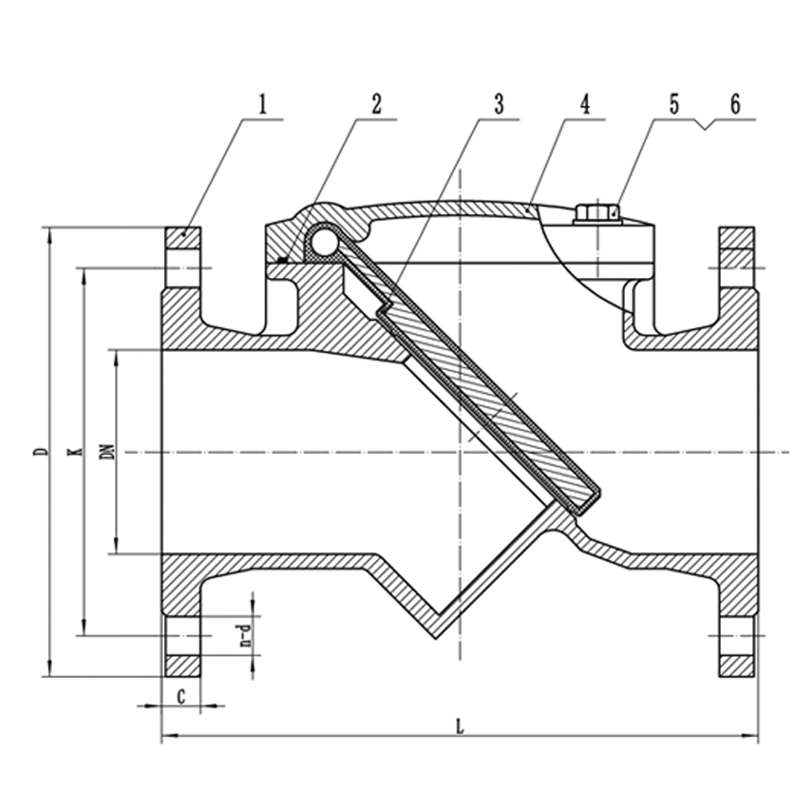

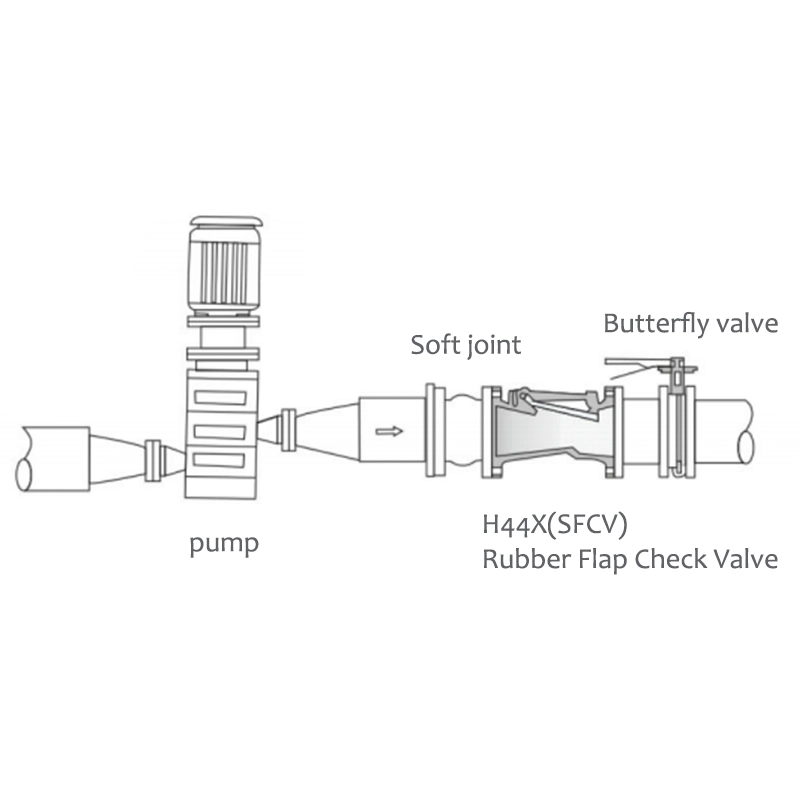

1.Rubber Flap Check Valve es una válvula de retención unidireccional que utiliza la deformación elástica del disco de la válvula de goma para empujar el disco de la válvula abierta cuando el medio fluye en la dirección hacia adelante.

2.El disco de la válvula se cierra automáticamente cuando el medio fluye en sentido inverso.

3.Tiene una estructura simple y un buen rendimiento de sellado

4.Se utiliza ampliamente en tuberías de líquido o gas para evitar el reflujo del medio.

CARACTERÍSTICAS

1.Alto rendimiento de sellado: El caucho y el asiento de la válvula encajan de forma flexible, con cero fugas

2.Bajo efecto de golpe de ariete: La elasticidad del caucho amortigua el impacto de cierre y reduce las fluctuaciones de presión de la tubería (el pico de presión se reduce en 40%-60%).

3.Resistencia a la corrosión: El material de caucho es resistente a la corrosión ácida, alcalina y por niebla salina, y es apto para aguas residuales y medios químicos.

4.Baja pérdida de presión: El canal de flujo no está obstruido cuando está completamente abierto, el coeficiente de resistencia es ≤0,3, y el efecto de ahorro de energía es significativo.

5.Fácil mantenimiento: No hay una estructura mecánica compleja, y el disco de la válvula se puede sustituir en línea (sin desmontar el cuerpo de la válvula).

SOLICITUD

1.Suministro de agua y sistema de drenaje: red de tuberías de alcantarillado municipal, prevención del reflujo de la tubería de descarga de aguas pluviales.

2.Fluido industrial: tuberías de transmisión de medios corrosivos en fábricas químicas y papeleras.

3.Riego agrícola: salida de la bomba de agua para evitar el reflujo de parada.

4.Drenaje del edificio: tuberías de drenaje del sótano, sistema de recuperación de aguas pluviales.

PRESIÓN DE TRABAJO

Presión máxima de trabajo 16 bar (230 psi).

ESTÁNDAR

Las pruebas de los productos se realizan de acuerdo con la norma GB/T13927 Prueba de presión de válvulas industriales.

RANGO DE TEMPERATURA

0 °C a 80°C.

REVESTIMIENTO

Revestimiento epoxi unido por fusión.

Deje su mensaje