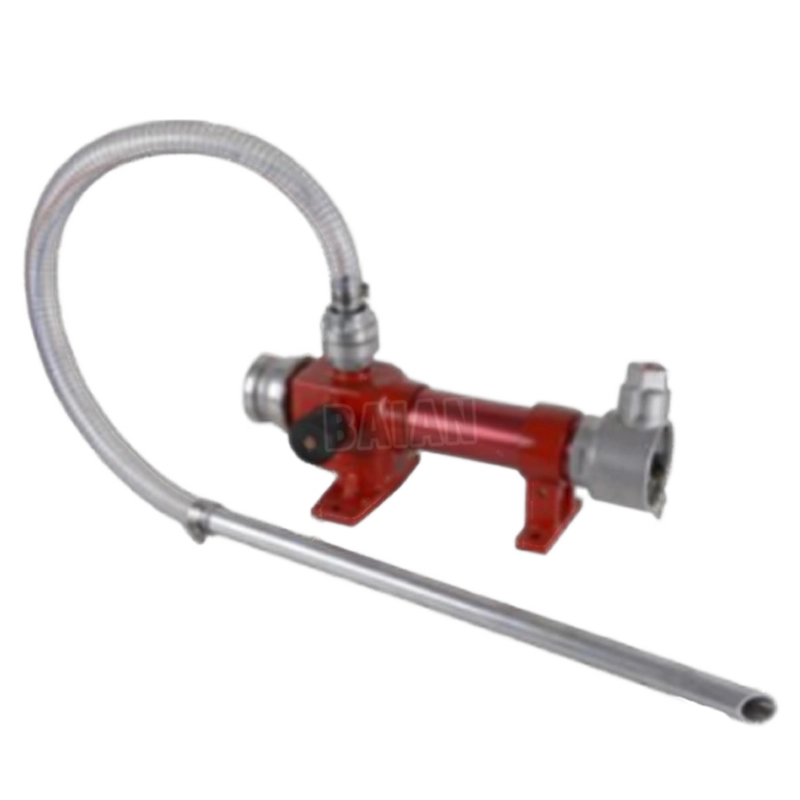

In-Line Foam Inductor Manufacturer

We In-Line Foam Inductor Manufacturer offers products with ANSI/BS4504/GB – standard proportional mixer flanges, galvanized pipe valve bodies, and spray – painted surfaces. Ideal for small/mobile foam fire – fighting in areas like fire trucks and small storage tanks, it uses a venturi – based principle, is ready – to – use, compact, and operates within 0.7 – 1.6 MPa pressure range.

See more at Proportioning and Mixing Equipment Catalog!

In-Line Foam Inductor Manufacturer

PHF/A

Specifications

1. Proportional mixer flange standard: ANSI / BS4504 / GB;

2. Valve body material: galvanized pipe;

3. Surface treatment: spray painting

Application scenarios

Applicable to small or mobile foam fire extinguishing systems:

Fire truck pipelines

Small storage tank area

Port terminal rapid fire extinguishing equipment

Scenarios that require lightweight and ready-to-use

Working principle

1. Negative pressure is formed when pressurized water flows through the venturi tube;

2. Negative pressure automatically sucks in foam liquid and mixes with water instantly at the throat;

3. The amount of foam liquid sucked in is controlled by the regulating valve to accurately maintain the set mixing ratio (such as 3%/6%).

Features

1. Ready to use: no storage tank, fast start-up response, simple maintenance;

2. Compact and light: direct pipeline connection design, minimal space occupation;

3. No power dependence: pure hydraulic mechanical structure, high reliability;

4. Cost advantage: no pressure tank/capsule is required, and the cost is significantly lower than that of tank mixers.

Working pressure

1. Inlet water pressure requirement: ≥0.7 MPa

2. Maximum working pressure: ≤1.6 MPa

3. Pressure loss: about 0.2~0.35 MPa