Core Function of Pressure Relief Valves

Pressure relief valves are crucial safety devices in industrial and building piping systems. Their main function is to automatically open and release the medium when the system pressure abnormally increases, preventing damage or accidents to pipelines and equipment due to overpressure. They act as a “pressure relief switch” for the piping system, constantly safeguarding the operational safety of the entire system. They are widely used in fire protection, water supply and drainage, HVAC, and industrial processes.

Flanged Pressure Relief Valves: Robust and Reliable Guardians

- Structure and Features

Flanged pressure relief valves are bolted to the pipeline flanges at both ends of the valve body, forming a robust and highly airtight rigid connection. Their structure typically includes a valve body, valve disc, spring adjusting mechanism, and pressure sensing element. They have strong pressure resistance and are suitable for medium to high pressure and large-diameter piping systems.

- Advantages and Applicable Scenarios

This type of valve has excellent sealing performance, high pressure resistance (commonly PN16, PN25, or even higher), low leakage rate, and can withstand significant pipeline stress and temperature changes. Particularly suitable for fixed installations and long-term stable operation, such as main water supply lines, fire pump outlets, and industrial main pipelines. Its standardized flange interfaces (e.g., GB, HG, ANSI standards) also ensure broad compatibility.

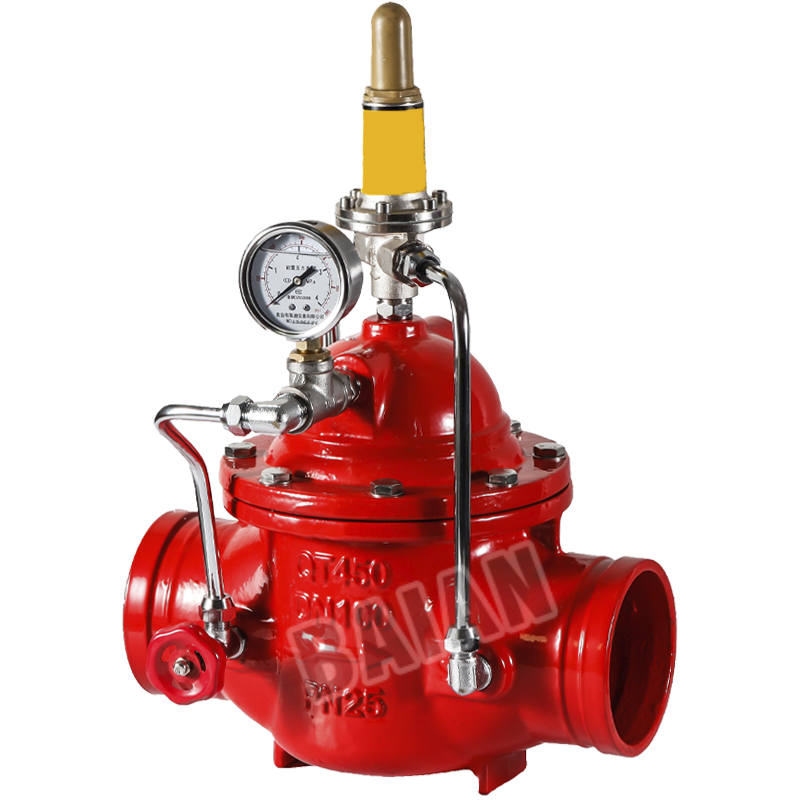

Grooved Pressure Relief Valve: A Flexible and Efficient Installation Solution

- Structure and Features

Grooved (clamp-type) pressure relief valves utilize the grooves on the valve body end to connect quickly with the grooves on the pipeline via rubber sealing rings and clamps. Its design integrates pressure sensing and relief mechanisms, resulting in a compact structure that eliminates the need for welding or extensive bolt tightening during installation.

- Advantages and Applicable Scenarios

The biggest advantage is convenient installation, significantly saving construction time and labor costs, making it particularly suitable for applications with limited space or frequent maintenance. The flexible clamp connection effectively absorbs pipeline vibration and slight displacement, reducing noise. It is widely used in fire sprinkler systems, air conditioning water systems, and medium- and low-pressure water supply and drainage pipelines—systems requiring high installation efficiency and moderate pressure.

Summary: Selection and Value

Choosing between flanged and grooved pressure relief valves requires comprehensive consideration of system pressure, pipe diameter, medium, installation conditions, and maintenance requirements. Flanged valves excel in high reliability and high pressure resistance, making them the preferred choice for heavy-duty systems; grooved valves, on the other hand, offer installation flexibility and cost-effectiveness, suitable for modern, rapid construction.

Regardless of the type, a qualified pressure relief valve delivers significant benefits: preventing equipment damage and safety accidents, ensuring stable system operation, extending pipeline life, and meeting regulatory safety requirements. Regular calibration and maintenance are crucial to ensuring its continued reliability. Equipping your piping system with the appropriate pressure relief valve is a wise investment in safety and efficiency.